Log Loaders

Description

Once the stems have been bucked into a series of log lengths, a machine is required to sort the logs and stack them into piles. Once enough logs of a specific sort has been accumulated, and a truck arrives, they can be loaded onto the truck and transported to their destination.

For small diameter short length logs (also called bolts) it is still feasible (but in all reality unrealistic) to load a truck by hand. There are also a number of ingenious ways of using pulleys and/or ramps to help manually load trucks. However, the majority of stacking and loading is carried out by a hydraulic loader.

Mechanical Configuration

Carrier Base

The carrier base for hydraulic loader impacts mainly the mobility and stability.

A wheeled loader - can move quickly around the landing area (see also front-end loader), but is not as sturdy as a tracked machine.

A tracked loader - is slower but more stable. It is also more expensive.

A Trailer Mounted Loader - The cheapest loader option is a trailer mounted loader. It is pushed or pulled into place by a tractor unit and then remains in place for the duration of the harvest. This means the extraction machine must deliver the stems within reach of the loader.

Loader Types

Knuckleboom loaders are swing machines with specially designed booms for handling logs. They may be track based, wheel based, or trailer mounted. The trailer mounted version is not capable of moving around a landing by itself. Knuckleboom loaders are designed with fast hydraulics for quick swing and boom movement. The grapples are pin mounted with a rotator which aids in positioning the logs for loading.

Wheel loaders and tricycle based machines are also used to load logs onto trucks. These machines use a set of forks with a grapple for picking up the logs. The main advantage of wheel loaders is the ability to pick up and load a larger number of logs, thus shortening the loading time.

Truck mounted loaders are boom type loaders mounted directly to the log truck. The operator station and boom are mounted together on a pedestal. The operator station consists of a seat with controls, no cab. Truck mounted loaders are only used to load shortwood and have the disadvantage of decreasing the payload that the truck can carry.

Typically used in woodyards, some self propelled loaders are mounted on wheeled, articulated chassis.

Grapples

There are a number of grapples that are used depending on the material being handled.

Bunching grapples generally have wider tongs for picking up and handling multiple stems. The alternative is a log grapple that has single tines.

Pulpwood grapples are designed for handling short wood. They are generally lighter duty grapples, designed to pick up multiple stems. Pulpwood grapples are usually bunching type grapples.

Log grapples are designed to handle tree length material in loading, delimbing, and yarding applications. These are generally more robust designs than the pulpwood grapples.

Butt-N-Top grapples are grapples with a heel mounted on either side of the grapple. This type of grapple is for handling tree length material in sorting and bunching operations. The heels provide greater control over the load. They are generally used for orienting logs in a truck butt to top for increased load capacity.

Boom type loaders often have a heel which assists in handling the logs by protecting the boom and controlling the end of the log. The heel may be either fixed or a ‘live’ heel. The live heel is integrated into the grapple with a separate hydraulic cylinder for increased control over the position of the log. A fixed heel may be attached to the grapple or the boom.

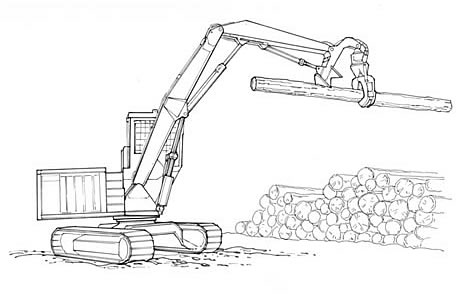

Figure 1 - Shovel loader with live heel.

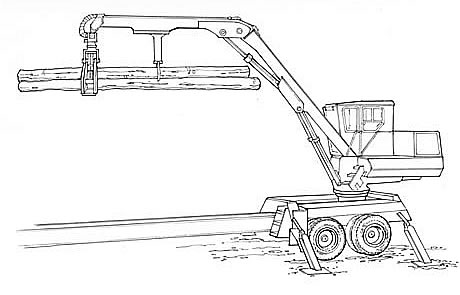

Figure 2 - Trailer mounted knuckleboom loader with fixed heel and bunching grapple.

Operational Considerations

Knuckleboom loaders are often used where their only need is at the landing and the tree size is not too large. Knuckleboom loaders are used in conjunction with pull through delimbers and sawbucks for processing trees at the landing.

Shovel loaders are used where piece sizes and volumes are too large for a knuckle boom loader to be effective. They are also commonly used where they are required to perform yarding functions in the system.

Four wheel drive loaders and tricycle loaders are used where the only function is loading and moving material that has already been processed. They may be used where their capability to move material with a bucket is required.