Felling Heads

Felling heads are attachments built to be mounted either to a boom or to the chassis on a base carrier. There are three categories of felling head, bunching heads, processing heads, and felling heads. Bunching heads are designed to handle multiple stems and do not have processing abilities. Processing heads are capable of felling and processing trees. Felling heads are capable of cutting and felling single stems with no processing capabilities.

Bunching Heads

Figure 1 - Bunching head.

Bunching heads, used on feller bunchers, have the ability to hold more than one stem at a time while cutting. They come in a variety of styles and configurations based on their method of cutting. There are three styles of cutting method employed by bunching heads: disc saw, bar saw, and shear.

The head holds the stems by means of gathering or grabbing arms and accumulator arms. The gathering arms are similar to standard grapples and reach out to grab the stem being cut. Accumulator arms are hinged, which allows them extricate themselves from behind the stems already in the accumulator so that the newly cut stem can be added to the bunch in the accumulator.

A disc saw is a large steel disc with cutting teeth attached at the edge. A disc saw is also called a hotsaw because the saw blade is always spinning. This saw is spun at very high speeds, in excess of 1000 rpms. The high speed and large mass of the blade allows these saws to cut trees extremely fast. Care must be taken when operating in rocky areas to avoid hitting rocks, as the sparks thrown may ignite the duff or wood chips. Another hazard is flying teeth when a tooth is broken off the disc.

One modification of the disc saw is called an intermittent hotsaw. This design operates similar to the bar saw in that the blade retracts into the head and only spins when it is needed to sever the stem.

Figure 2 - Shear head.

A bar saw is simply a large chainsaw bar mounted on the felling head. The saw retracts into the head when not needed. When it is needed, the saw begins spinning the chain and rotates out to cut the stem. Bar saws have the potential to decrease the risk of fire starts but operate more slowly than disc saws.

A shear works on the same principal as anvil-type pruning shears used by gardeners. A hydraulic cylinder closes the shear against the anvil to sever the tree. This method is slower than either the disc saw or the bar saw. It also has the tendency to shatter the end of the log, especially during cold weather, and thus is not a good choice for high value material.

Processing Head

Figure 3 - Processing head.

Processing heads are capable of felling trees and performing some sort of processing on the stem. The most common processing heads are capable of delimbing and bucking stem into logs (this is commonly referred to as a “cut to length” system).

Most processing heads are designed to fell and process one stem at a time. The recent focus on biomass and smaller diameter material has spurred the development of processors capable of handling multiple stems. A new type of head has been developed recently that is capable of both felling the tree and converting the stem into chips.

The main components of a processing head are a bar saw, delimbing knives, and feed rollers. The delimbing knives hold the stem while it is being cut and processed. The bar saw fells the tree and bucks the stem to length. The feed rollers move the stem through the head for delimbing and bucking. The delimbing knives have sharp edges designed to shear the limbs from the bole while the stem is being fed through the head by the feed rollers.

The head is capable of measuring length and diameter as the tree is being moved through the head. Length is usually measured by a wheel attached to the head, or by the feed rollers. Diameter is usually measured by measuring the opening of the delimbing knives. The length and diameter is then displayed to the operator on a monitor in the cab. The operator is capable of cutting specific lengths based on the diameter of the material to achieve high value utilization. Computer control systems are available that can be programmed to automate the processing task based on the species and utilization parameters programmed into the system.

Some processing heads have special delimbing knives that can debark certain species such as aspen and eucalyptus. This improves the value recovery of these species.

A processing head has been developed that replaces the bar saw with a masticator style drum. This drum cuts the tree and the feed rollers feed the tree into the drum to chip it.

A danglehead processor is simply pinned to the boom. The head hangs vertically from the boom until the tree is cut. The tree then pulls the head into a horizontal configuration as it is falling. There is limited control over the falling direction. Some dangleheads do have hydraulic rams that control the speed of the fall.

A fixed head is attached to the boom through a rotator and hydraulic cylinder. This provides the operator with control over the rotation and vertical orientation of the head, which in turn provides control over the direction and rate of fall of the tree.

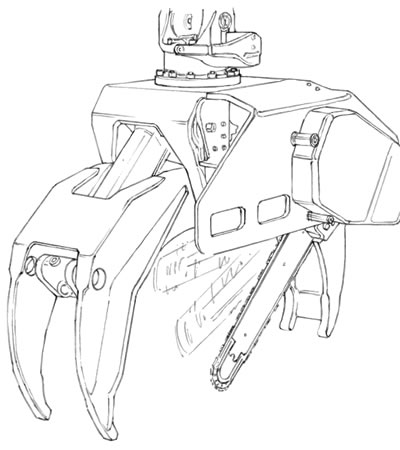

Felling Head

A felling head is a grapple with a bar saw attached perpendicular to the grapple. It is capable of cutting trees and controlling the direction of fall.

Figure 4 - Felling head.

Grapple Saw

A grapple saw is a grapple with a bar saw attached parallel to the grapple. They are generally used at landings to perform some trimming of material.

Figure 5 - Grapple saw head.