Chippers

Description

Chippers are machines capable of reducing trees to wood chips. Chippers differ from grinders in that they produce uniform sized chips depending on the equipment settings.

Mechanical Configurations

Chippers come in a large variety of configurations. Common features include a feed mechanism, a set of rotating knives, which may be either drum or disc mounted, an anvil, and a discharge chute. Chip size is determined by the distance from the anvil to the knives, the distance between the knives on the drum or disc, the feed speed, and the speed the drum or disc rotates. The feed mechanism is usually a set of feed rollers at the throat of the chipper. Some chippers may have conveyors to assist in feeding the chipper.

Figure 1. - Trailer Mounted Chipper

A drum chipper has a cylindrical drum on which the cutting teeth are mounted. A disc style chipper mounts the cutting teeth on a large steel disc.

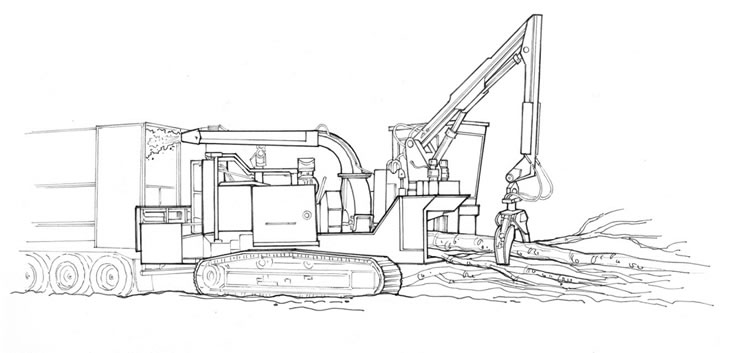

Chippers may be trailer mounted or self propelled. Trailer mounted chippers may have a pintle hitch, king pin, or ball hitch. Self propelled chippers are usually track mounted.

Figure 2. - Self Propelled Chipper

Some chippers are equipped with a loading arm and grapple for self loading. Some have a cab for the operator.

Some chippers have integrated delimbing/debarking functions. These are used to produce clean chips that may be used for fuel or pulpwood.

Operational Considerations

Physical Limitations

Trailer mounted chippers are generally used at a landing where slopes are limited. Self propelled chippers may be operated in the stand where slopes do not exceed the safe operating limits of the chipper.

Chippers are capable of handling material that fit within the throat opening of the chipper.

Treatment Options

Chippers may be used in virtually any treatment scenario.

Safety Concerns

Chippers require diligence when working around them. There is a very real danger of the operator getting pulled into the chipper if care is not taken when feeding the chipper. Eye and hearing protection must be worn around chippers.

System Interactions

Chippers work with virtually any system used to harvest trees. Clean chips will require some method to delimb and debark the material before chipping.

Research

The following is a selection of representative research studies and reports done on harvest systems that include chippers. These reports may be used to get an idea of productivity and impacts of different systems and uses of chippers as well as some of their limitations. When reading these reports, keep in mind that they describe specific systems and stand treatments. Trying to apply the lessons learned from these reports to systems and treatments outside of the studies’ scope may have unintended or unforeseen consequences.

This is not a complete listing of research on the use of delimbers. Additional information can be found at the USDA Forest Service Treesearch website. This site provides reports on research performed by Forest Service Research and Development scientists and their collaborators.

- Title: Forest fuel reduction through energy wood production using a small chipper/CTL harvesting system

Author: Bolding, M. Chad; Lanford, Bobby L.

Date: 2001

Source: In: Wang, Jingxin; Wolford, Michelle; and McNeel, Joe. Eds. Proceedings of the 24th annual Council on Forest Engineering meeting: Appalachian hardwoods; managing change; 2001 July 15-19; Snowshoe, WV. Corvallis, OR/USA: Council on Forest Engineering: 65-70. [CDROM]

Description: In the summer of 2000, fire destroyed millions of acres of forest across the United States. This study investigates the feasibility of harvesting to reduce forest fuel buildup and produce energy wood. Cut-to-length (CTL) harvesting coupled with a small in-woods chipper provides a low impact way to harvest pre-commercial trees and tops along with merchantable logs. While CTL harvesting systems have been used successfully with full sized chippers, it requires two or three CTL teams to keep the chipper busy. A smaller, less expensive chipper which is expected to have similar productivity to a single harvester-forwarder team and have reasonable ownership and operating costs, will allow operations to stay small and efficient. A CTL/small chipper system is projected to be an efficient way of reducing forest fuel loads and less expensive than fire suppression and stand-replacement costs after wildfire. Energy wood from fuel reduction harvesting could be used as an alternative energy source. The benefits of energy wood become more important as fuel prices increase. The feasibility study suggests that if energy equivalent values were obtained, a CTL/small chipper system could provide income rather than expense for site conversion, cleanup operations.

Products and Markets

Chippers can be used to produce material for pulpwood, pellets, hog fuel, landscaping, and any other application that requires uniform chips.