Delimbers

Introduction

Gate, flail, and pull-through delimbers are landing based methods for removing limbs from the boles of trees. These are relatively low cost methods for delimbing. They are used where the quality of the delimbing job is not critical to either the purchaser or the post processor.

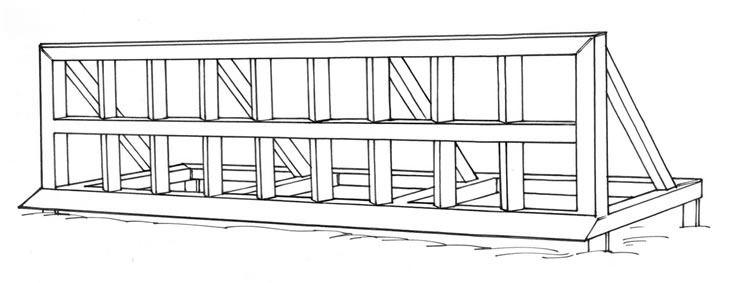

Gate Delimber

Gate delimbers are welded structures consisting of steel tubing welded in a grid pattern. Gate delimbers may have an integrated support structure, or consist of a simple flat grid that is tied to standing trees. A grapple skidder backs a load of trees through the gate, breaking the limbs off of the bole in the grid.

Figure 1. - Gate Delimber.

Pull-Through Delimber

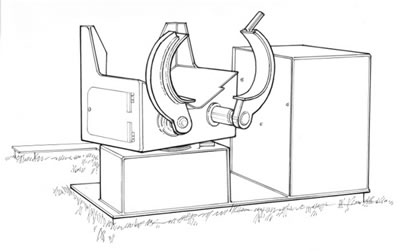

Pull-through delimbers are processor heads mounted horizontally, lacking a feed mechanism or measuring capabilities. A pull through delimber can either be a standalone unit, or it can be mounted onto the same trailer as the loader for stability and convenience. The loader picks up a tree, placing it in the pull-through delimber. The delimber usually has three knives that wrap themselves around the stem, at which point the loader pulls the stem through, removing the limbs from the tree. Most pull-through delimbers have a topping saw in them that will cut off the top.

Figure 2 - Pull-through delimber.

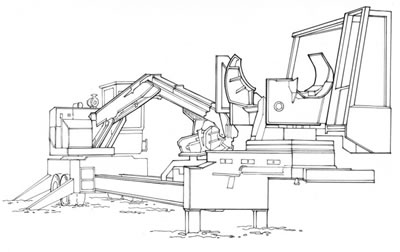

Figure 3 - Trailer Mounted pull-through delimber with saw.

Flail Delimber

If dealing with relatively small trees from dense stands with small limbs, a machine that can be very effective is the chain-flail delimber. Flail delimbers consist of chains mounted on rotating drums. The chains break the limbs off stems fed through the delimber. Flail delimbers may be self-feeding or require a loader to pull the stems through the delimber. Either the loader or the skidder will pull through a bunch/turn of stems and the chains not only ‘beat and break off’ the limbs, it also effectively removes most of the bark. This makes it particularly useful in an operation where the primary product is ‘clean’ chips, that is, chips that are going to be used for making pulp and paper. Clean chips must have very low bark content - often specified as being less than 1 % of the total volume.

Figure 4 - Delimber (on right) feeding into a chipper.

Operational Considerations

Physical Limitations

These delimbing methods are used at the landing where there are few limitations other than space for the slash produced.

Treatment Options

These delimbers are used where full trees are being delivered to the delimber. The form of the trees, single bole trees, and the size of the tree that can fit through the throat of the delimber or grids in the gate generally limit them. Flail delimbers are generally not limited by tree size, but by the size of the limbs being removed.

System Interactions

Gate Delimber

Gate delimbers are placed near the landing to enable processing just prior to entering the landing. Gate delimbers are used in conjunction with a chipper or as part of a tree length system loading the delimbed stems directly onto a truck. Often additional work is required to remove any limbs or stobs that have been left by the gate delimber.

Gate delimbers are most often used with a grapple skidder and manual or feller buncher felling.

Pull-Through Delimber

Pull-through delimbers achieve a cleaner stem than gate delimbing, and in tree length systems, often do not require any additional processing prior to loading on a truck. A loader is required to load and pull stems through the delimber. Pull-through delimbers work in conjunction with any system delivering full length stems to the delimbing site.

Flail Delimber

Flail delimbers are often used in tandem with chippers to produce clean chips. Clean chips are chips without bark and leaf material.

Research

The following is a selection of representative research studies and reports done on harvest systems that include delimbers. These reports may be used to get an idea of productivity and impacts of different systems and uses of delimbers as well as some of their limitations. When reading these reports, keep in mind that they describe specific systems and stand treatments. Trying to apply the lessons learned from these reports to systems and treatments outside of the studies’ scope may have unintended or unforeseen consequences.

This is not a complete listing of research on the use of delimbers. Additional information can be found at the USDA Forest Service Treesearch website. This site provides reports on research performed by Forest Service Research and Development scientists and their collaborators.

- Title: Delimbing hybrid poplar prior to processing with a flail/chipper

Author: Hartsough, Bruce R.; Spinelli, Raffaele; Pottle, Steve J.

Date: 2002

Source: Forest Products Journal, Vol. 52(4): 85-94

Description: Processing whole trees into pulp chips with chain flail delimber/debarker/chippers (DDCs) is costly. Production rates of DDCs are limited by the residence time required to remove limbs and bark. Using a pull-through delimber, we delimbed trees prior to flailing and chipping, with the objective of speeding up the latter processes. Pre-delimbing increased the productivity of the DDC by about 10 percent. The reduced cost of flail/chipping did not cover the additional cost of delimbing with the machine mix tested, but changes to equipment and operating conditions might improve the situation. In the test configuration, the delimber processed 175 trees per productive hour, about half as many as the DDC. Delimbing separated about 35 dry pounds of limbs per tree, which may have higher value than the mixture of limb and bark residues produced by the DDC from whole trees. - Title: Production and Costs of the Chambers Delimbinator in First Thinning of Pine Plantations

Author: Mooney, Scott T.; Boston, Kevin D.; Greene, W. Dale

Date: 2000

Source: Forest Products Journal Vol. 50, No. 4

Description: Production and quality measures were collected and analyzed for a new chain-flail delimbing machine, Chambers Delimbinator, on two operations in central and southwestern Georgia. The first operation, Logger A, used two skidders and one loader while the second operation, Logger B, used two skidder and two loaders. Lobber B with the lower cycle time and larger piece size produced an average of 57.4 tons per hour, while Logger A produced an average of 39.2 tons per hour. With defects defined as a branch great that 1 inch in length and 1 inch in diameter, the Chamber Delimbinator produced similar delimbing quality for both logging operations.