Brief History of the Ax

- Evolution of the Ax in America

- Ax Types, Patterns, and Uses

- American Felling Ax

- Double–Bit Ax

- Broad Ax

- Other Axes and Hatchets

- Adzes

- Decline of the American Ax

I've always had a passion for axes. I received my first ax—a toy—when I was 8 years old, and my first real ax not long afterwards. Since that time, for over 45 years, I've used and collected all kinds of axes and adzes in my professional work restoring historic buildings and structures.

We cannot explore everything there is to know about axes in this publication. What I would like to share with you is a brief background on the development of axes, the hanging and sharpening of axes, how to use an ax, and detailed information on certain ax patterns. I've tried to place the discussion within the context of working with axes today and from a historical perspective of their use within the USDA Forest Service.

In An Ax to Grind: A Practical Ax Manual, you'll find:

- A brief look at the history of the ax, especially its

evolution in America

- Types and patterns of axes and adzes, showcasing some

examples from my personal collection and some from old catalogs

- How to hang and sharpen an ax, two essential skills for

anyone using an ax

- Various examples of using axes, incorporating historical

material

- Where to buy a good ax

- Some other good references about axes that you may find useful.

This manual is intended to be a companion to my video program, An Ax to Grind (99–01–MTDC). The video (Figure 1) was produced by the Missoula Technology and Development Center (MTDC). Copies are available from the center. I hope you'll take a look at it.

Figure 1—The video program, An

Ax to Grind

(99–01–MTDC), is a companion to this manual.

The video is available from Missoula Technology

and Development Center.

Evolution of the Ax in America

...having an ax to grind

Getting even for a perceived wrongdoing.

...barking your knuckles

Scraping your knuckles on the side of a log while hewing it.

...cant get the hang of it

Cant get it right, originally referring to the way an ax handle was mounted to the the ax head.

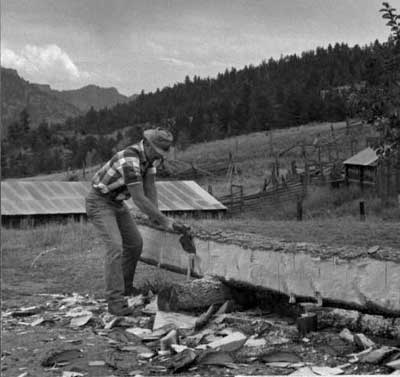

Although we still make references to axes in our daily speech, most Americans have a limited knowledge about them (Figure 2), including how to use and properly maintain them. But the ax, in one form or another, has been around for over 10,000 years—even longer if you consider some of the crude stone tools used as axes by early man.

Figure 2—Barking your knuckles comes with

the territory when you choose to hew with a broad ax.

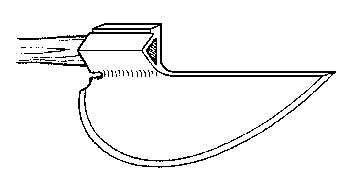

While the ax has gone through transformations from stone, copper, bronze, and iron to steel, its overall shape and function have remained consistent (Figure 3). The ax was the first real woodworking tool, one of only a few available for a long period. For centuries the ax was one of mankind's most useful tools.

Figure 3—Parts of the ax. (Courtesy of Gränsfors

Bruks AB, Sweden.)

Click for the long description.

The early iron and steel axes used in America had European roots. Henry J. Kauffman, in his introduction to American Axes (1994), wrote:

Part of the problem of focusing attention on the American axe arises from the fact that the earliest ones used here were made in Europe, and certainly the first ones made here were European in character. Thus, in the earliest colonial times a dividing line could not be drawn between the two categories. As a matter of fact, the object was really a European–American axe. Because iron, unlike wood, is similar regardless of the place it was made, the essential substance of an axe does not help to identify its origin. Short of some identifiable maker's mark, the manufacturers of most of our early axes must remain anonymous.

It seems certain that most of the first axes made in North America were made and used on the Atlantic seaboard, a few exceptions occurring when trading companies brought in blacksmiths to their centers of exchange to repair and resharpen axes. As settlers moved westward and southward, their needs were supplied by smiths who went with them and were responsive to individual needs. This procedure was the beginning of very high specialization in the forms of axes, a differentiation which was picked up by the big manufacturers in the nineteenth century. The axes were mostly of the felling variety, but there were other purposes for which an axe was needed.

The pace of specialization increased; as evidence of this trend, one manufacturer informed the writer that at one time the company manufactured about three hundred different types. The president of the Mann Edge Tool Company, in Lewistown, Pennsylvania, reported that in 1969 they were producing seventy different patterns; however, the bulk of their production involved only about twenty.

The ax became quite specialized in Europe during the Middle Ages and afterward. When European colonists dispersed throughout the New World, they brought their tools and their knowledge with them. It is not surprising to see the appearance of trade axes (Figure 4 and Figure 5) and Germanic goose–wing hewing axes. We also see examples of older European–style specialized axes (Figure 6, Figure 7, and Figure 8) in America.

Figure 4—A 17th–century trade ax, typically

made in northern Spain and traded by the

French with American Indians.

Figure 5—An early 20th–century Collins ax

manufactured for the South American market.

Note the similarity in design of the two axes.

Figure 6—An 18th–century mortising ax or

twibil gives an idea of the specialization

even in early axes. Length, 4 feet.

Figure 7—An 18th–century shingling hatchet

is another specialized ax. Ax head is 5½

inches long by 4 inches wide.

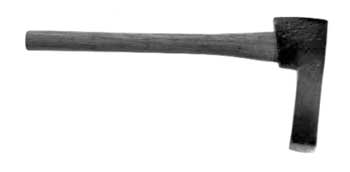

Figure 8—An 18th–century splitting ax,

with straight handle typical of early axes.

Americans modified European axes for two principal reasons (Kauffman 1994). First, the European axes were not as well suited to the virgin stands of huge trees found in America as they were for the smaller timber stands of Europe. The European axes were good tools for hewing, but less adequate for felling. The second reason, Kauffman suggests, is that many of the Europeans who left their homelands for an uncertain future in America were prepared to adapt to survive. Their pioneering spirit bred ingenuity.

The need for a better felling ax, the need to process huge amounts of timber during America's settlement, and American ingenuity made development of the American felling ax inevitable.

During the 19th century, America's agrarian society was not as mobile as our society is today. People lived their lives in relatively small geographic areas. This is one explanation of the hundreds of different ax–head patterns that developed over the last 150 years.

The individual skills of local blacksmiths and their view of what an ax needed were important factors in the development of ax–head patterns. Ax patterns became a matter of regional preference.

Around the turn of the 19th century, more than 300 different ax–head patterns were being manufactured in the United States. Many were nearly identical. To simplify identification and eliminate unnecessary or duplicate patterns, the Ax Manufacturers' Association agreed to set a standard, which resulted in a standard chart of ax patterns (Figure 9).

Figure 9—Some standard patterns manufactured

by True Temper Kelly in 1925.

Certain ax patterns become popular within a given geographic area, such as the Jersey (my particular favorite), the Michigan, the Dayton, and the Kentucky (Figure 10). At times, ax head patterns included a name that related to their use. For example, the rafting ax pattern originated in the day when logs were rafted down rivers.

Figure 10—Some Collins Company "American axes"

from the company's 1921 catalog.

Ax–head patterns were also adapted to the timber that was available in the local area. The double–bit ax was originally developed in Pennsylvania (Figure 11). But the double–bit axes with a long, narrow, heavy ax head and a long handle, were developed for cutting large trees in the Pacific Northwest. Some of the patterns from this area were the Puget Sound, the Young's felling pattern, the Redwood pattern, and the Humboldt pattern.

Figure 11—A 19th–century "Hand Made"

double–bit ax.

American Felling Ax

During the period in which the trade ax was being introduced to the North American Indians, the felling ax was brought to America by settlers from England, France, and Spain.

The 17th–century felling ax was made of two pieces of iron that were hammer welded down the center of the poll surface. Later axes had a thin poll with a flat surface. When North American blacksmiths began making the felling axes, they forged the poll side of the pattern longer in order to make a lap weld, which gave more welding surface. This produced a heavier poll with more weight behind the handle, providing better balance. In essence, this design is the modern ax that we use today (Kauffman 1994) (Figure 12).

Figure 12—Winchester ax and hatchet, Michigan

pattern, typical of the American felling ax.

An edge tool maker's advertisement in the Pennsylvania Packet and Daily Advertiser on July 7, 1789, shows that the American felling ax was fully developed then. The illustration closely resembles the Kentucky pattern made by the Douglas Ax Company and illustrated in its 1863 catalog. The Jersey pattern, my personal favorite, is very similar to the model of 1789. It is still available. In the mid–19th century, some of the American axes were still made of both iron and steel. An iron poll and a high–carbon–steel single–bit ax appears in an advertisement in the October 29, 1859, issue of Scientific American (Kauffman 1994).

The addition of the poll by an unknown North American blacksmith is what makes the American felling ax unique. Late 18th–century iron axes often had steel insert cutting edges. Earlier European axes with their long blades were awkward to use. When North Americans ground down the blades after sharpening them many times, they discovered that they could use them to cut more accurately. These axes had better balance and geometry. The blade wobbled less during the swing. After this discovery, American axes were made with shorter, wider blades.

In the late 18th century, some axes became almost square. These axes are often referred to as the American ax (Figure 13). Introduction of he Bessemer process for making steel in the late 19th century made steel affordable. The entire ax blade could be made of steel. Polished steel axes reduce the friction between the blade and the log. The ax blade can be made even thinner, allowing size and weight to be reduced while maintaining cutting efficiency. Making the entire ax wider with a heavier poll gave it more balance than the narrow, long–bladed English or European ax with little or no poll (Kauffman 1994).

Figure 13—My favorite American felling ax, a True

Temper Kelly Perfect with a Jersey head and 32–inch

straight hickory handle.

The head of a full–size single–bit ax or poll ax weighed 3 to 6 pounds. The handle was 30 to 36 inches long.

The single–bit felling ax, or American ax, became the international standard for quality axes.

Double–Bit AxThe first double–bit ax was probably made by William Mann in Pennsylvania at about 1850. The Mann Edge Tool Company is one of the few American companies still in the business of making axes. By 1860 the double–bit ax was very common in the Northeast. The double–bit was not widely popular until the last quarter of the 19th century when it came into its own in the Pacific Northwest (Figure 14).

Figure 14—Three double–bit patterns

available from Collins in 1921.

The double–bit ax weighed from about 2½ to 5 pounds and had a handle that was 26 to 42 inches long (Figure 15).

Figure 15—Three representative double–bit patterns:

Bluegrass Western pattern double–bit ax(top left);

True Temper Kelly Perfect Michigan pattern double–bit

ax (top right); and a 2½–pound reversible cruiser

ax, sometimes used for ax throwing (bottom).

Which is better, a single–bit or double–bit ax? No other question is likely to raise as much controversy among ax enthusiasts as this one. Although the single–bit or poll ax was developed first and has remained popular, the double–bit developed a strong following because of its balanced feel and versatility. Typically, one blade was sharpened to a finely honed, narrow "felling edge," while the second blade was ground slightly blunter, and used for knots, cutting near the ground, or in other instances where a finely sharpened blade was more likely to be damaged.

The double–bit ax remains a popular utility ax in the Western United States, especially among agencies like the USDA Forest Service. The single–bit ax also remains popular. All of the competition axes are single–bit axes. In my opinion, a single–bit ax is a more efficient cutting tool; the double–bit is more versatile.

Broad AxOther special–purpose axes helped develop America. The hewing ax (also called broad ax or side ax) was used to square timber or flatten the sides of logs. It was used primarily for log buildings and timber framing, either in house or barn construction. Hewn timber was also used for railroad ties and trestle bridges.

The goose–wing broad axes (Figure 16) brought to America by German settlers were the earliest hewing axes commonly used in this country. These axes were first used in Bucks County, PA. An earlier pattern of hewing ax known as the medieval goose–wing ax occasionally shows up (Figure 17). Goose–wing broad axes were made in both left– and right–handed models. The goose–wing handle was offset to the left or right by fitting it into a bent metal tube forged to the bit. Later hewing axes, known as American broad axes, had a handle that allowed the head to be taken off and reversed for use by right–handers or left–handers.

Figure 16—An 18th–century Germanic goose–wing

hewing ax. There are maker's marks hammered

into the blade.

Figure 17—A medieval goose–wing ax that

differs from the Germanic goose–wing axes

brought into the United States by early settlers.

Some American broad ax patterns had geographic names. The most popular were the Pennsylvania, Western, Canadian, and, the New Orleans pattern, my favorite (Figure 18a, Figure 18b, Figure 18c, Figure 18d, and Figure 18e). Until the 1930's the Western and Canadian patterns were used to hack railroad ties. The slang expression for a person who made railroad ties was a "tie hacker."

Figure 18a—Beatty Pennsylvania broad ax.

Figure 18b—Early 20th-century Douglas, New

Orleans broad ax—my favorite.

Figure 18c—Early 20th–century Beatty knife–edge

tie hacker's broad ax.

Figure 18b—Kelly 20th–century Canadian broad ax.

Figure 18e—A 19th–century shipwright's

mast broad ax.

The hewing ax is the preferred tool for flattening the surface of round logs. In past centuries, wood beams were often made by splitting the logs with some type of mallet and wedge, or glut. Then they were surfaced with an adz or a hewing ax. When iron axes became available, the hewing ax almost replaced the adz. Hewing axes were frequently used to roughly square the logs before they were sawn into boards with a pit saw.

Even after the sawmill became common, the hewing ax was still used for hewing beams and planks in the Northwest. It was often easier to ell the tree, hew it square into cants, and skid the cants to the building site rather than to load and transport round logs to the sawmill where they would be sawn before being brought back to the building site. The hewing ax has been used in the same manner for about 2,000 years.

Other Axes and HatchetsAxes have other uses besides felling timber and building houses. Splitting axes are used for splitting firewood or rails. Hatchets, with their short heads and handles, are used in the building trades, and for camping and hunting (Figure 19). Some axes and hatchets are used specifically for mortising (Figure 20), wood carving, flooring, shingling, and carpentry (Figures 21a and Figure 21b). Special competition axes are also used in logging contests where people chop while racing the clock and each other (Figure 22).

Figure 19—Plumb 2½–lb boy's ax with

19–inch handle—my favorite for log cabin work.

Figure 20—An 18th–century mortising ax.

Figure 21a—Some 20th–century Plumb hatchets

and hand axes.

Figure 21b—More 20th–century plumb hatchets

and hand axes.

Figure 22—A Tuatahi cempetition ax. This New

Zealand company specializes in custom-made axes

and competition crosscut saws.

Some axes weren't used for cutting wood. Ice axes were used to cut ice from lakes in the winter so the ice could be used for refrigeration during the summer (Figure 23). Sod or turf axes were used to chop sod for sod houses (Figure 24). People have used axes as a weapon for centuries. Fire axes are used to break down doors to enter burning buildings. The Pulaski is an ax tool used to fight wildland fires (Figure 25). An ax known as a butchering ax was used to kill cattle (Figure 26). Axes called "salesman samples" were miniature versions of full–size axes. Salesmen would carry them to hardware stores to demonstrate their wares.

Figure 23—A 19th-century ice ax

for harvesting pond ice.

Figure 24—A 19th–century sod ax

for building sod houses.

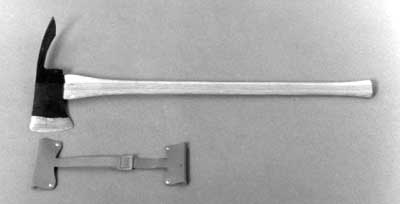

Figure 25—The Pulaski is a popular wildland

firefighting tool that combines an ax

with a grubbing hoe.

Figure 26—A 19th–century butchering ax.

Adzes

The adz is another hewing or dressing tool (Figure 27a, Figure 27b, Figure 27c, and Figure 27d). It has a head that gives it the appearance of a hoe, but it is tempered and sharpened to cut wood. The adz is primarily used for dressing or planing timber that has been hewn by a broad ax. An adz is used for the final dressing in some of our finer hand–built structures.

Figure 27a—Collins lipped shipwright's adz.

Figure 27b—Plumb railroad adz.

Figure 27c—Modern carving ax or adz.

Figure 27d—Douglas carpenter's adz.

Some of the leading American ax companies have included: Collins Company, Mann Edge Tool, Kelly Axe or True Temper Kelly, Plumb Axes, and American Axe and Tool Company. When factory production first began, axes were produced by individual blacksmiths hired to make a complete ax. Gradually an assembly line was introduced. Improved steels and more efficient forging processes took most of the hand labor out of ax manufacture. The manufacturing process and materials evolved from individual blacksmiths hammering out axes one at a time to the giant drop hammers used today to stamp out fully formed ax heads.

During the 19th century, axes provided the best technology to meet the needs of the burgeoning forest products industry. Manufacturers produced hundreds of patterns for both general utility and specialized uses.

The use of American axes and their quality were probably at their peak during the period from 1850 to 1950 (Figure 28). Beginning about 1870, ax production began to drop due to the increased use of the crosscut saw as a felling tool. The ax continued to play an important role for swamping and limbing trees, but its role was diminished.

Figure 28—During the heyday of American axes,

companies went to great lengths to promote their

axes, like this Kelly "Best Ax Made" broad ax.

The introduction of the power saw was the death knell of the ax and the crosscut saw. By the late 1950's and early 1960's, lightweight, efficient chain saws had taken over almost all of the work that previously had been accomplished with an ax–felling, bucking, and limbing.

If you search the Internet for ax, axe, or axes, you will probably find more sites related to guitars (referred to as "ax") than you will to those dealing with cold, hard steel. But if you focus on work in the woods rather than on the Internet, you will see that the ax still occupies an important place as a woodworking tool.

A Swedish company, Gränsfors Bruks AB, still manufactures hand–forged axes (Figure 29). Gabriel Brånby of Gränsfors Bruks provides a good summary of the modern role of the ax (Gränsfors Bruks 1997):

In a certain way we are back at the time before the entry of the booming forest industry. There are no axe–using forest workers any longer. The millions of cubic feet of pulpwood and timber that today arrive at the forest industries have never been grazed by an axe. The chain saws, harvesters and logging machines have taken over completely. Today most axes are used in small–scale activity by people like homeowners, firewood cutters, campers, hunters, joiners, woodworkers, log builders.

Figure 29—Modern hand–forged broad ax made by

the Swedish Company, Gränsfors Bruks AB.

Thousands of new axes are sold every year, mostly for the activities Brånby describes. Some historic axes are sold or traded by collectors (Figure 30). In the Forest Service, axes still play a critical role in designated wilderness areas where mechanized or motorized equipment is prohibited by law. In these areas, axes, adzes, and crosscut saws are needed for clearing trails, cutting firewood, managing forest fires, and maintaining or restoring administrative buildings.

Figure 30—This modern blacksmith–made trade hatchet

might be just the right gift for your sweetheart

on Valentine's Day.

Outside wilderness, axes and adzes are used for historic building restoration and as lightweight, convenient, affordable alternatives to chain saws. To at least a few recreational wood cutters and craftsmen, the rhythmic sound and motion of chopping are more appealing than the whine and exhaust of a chain saw.

This look at the history of the ax and its evolution in North America is not complete. Four excellent references for more detailed study are: Henry J. Kauffman's American Axes (1994); Charles A. Heavrin's The Ax and Man (1997); Alan Klenman's Ax Makers of North America, and Henry Mercer's Ancient Carpenter's Tools (1960). Full citations for these sources are in Selected References.