Chapter 5—Crosscut Saw Tasks and Techniques (Suggested time: 2 hours)

Chapter 5—Crosscut Saw Tasks and Techniques (Suggested time: 2 hours)

Chapter objectives:

- Students will understand the different features of

crosscut saws.

- Students will understand how a saw cuts and how the

saw's components function.

- Students will test and assess a crosscut saw's performance,

and recommend corrective measures.

- Students will recognize the various configurations of

saw handles and their relationship to saw performance

in various applications.

- Students will understand the value of a good saw

maintenance program.

- Students will demonstrate how to properly sheathe

and transport a saw.

- Students will learn the procedures for limbing, bucking,

and felling.

- Students will understand the types of binds.

Historical Origin of the Crosscut Saw

The crosscut saw did not come into use until the 15th century. Early saws had a plain peg tooth design. Saws were used in Colonial America and were being manufactured in this country by the mid-1800's. Saws were not used for felling timber until around 1880. The machinery to make these vintage saws is no longer available. Crosscut saws manufactured today are lower quality.

Different Types of Crosscut Saws

Crosscut saws generally can be divided into two types: one- and two-person saws.

One-Person Crosscut Saws—A one-person crosscut saw's blade is asymmetrical. The saw has a D-shaped handle. The saw also has holes for a supplemental handle at the point (tip) and the butt (near the handle). The saws are usually 3 to 4½ feet long (figure 5-1).

Figure 5-1—One-person crosscut saw.

Two-Person Crosscut Saws—Two-person crosscut saws are symmetrical. They cut in either direction on the pull stroke. Vintage saws were made from 4 to 7 feet long in 6-inch increments.

Two-person crosscut saws (figure 5-2) manufactured today are flat ground. Most vintage saws were either straight taper, crescent taper, or flat ground. The saws have one or two holes, or a groove, on the ends of the blade where removable handles can be attached. Most vintage saws had teeth all the way to the ends of the blade. Saws manufactured today do not.

Figure 5–2—Two-person crosscut saw.

Two-Person Crosscut Saws

Felling Saws—Felling saws are best suited for felling standing timber. They cut best in a horizontal position. Felling saws have a concave back and are narrower than bucking saws (figure 5-3). The combination of a concave back and narrower width give felling saws the following characteristics:

- The saw is more flexible.

- The saw is lighter, so less effort is needed to use it.

- The sawyer can insert a wedge sooner.

Crosscut saws usually have two handles. Many vintage felling saws have one handle hole in each end.

Bucking Saws—Bucking saws can be used for felling. Some saws were manufactured to try to incorporate the best characteristics of both types of saws. Bucking saws have a straight back; they are much thicker than felling saws, so they are heavier and stiffer (see figure 5-3).

Figure 5-3—Comparison of felling and bucking saws. Concave-backed

felling saws often have one handle hole per side. Straight-backed

bucking saws can have two handle holes per side.

Because the bucking saw usually is operated by one person, it cuts on both the push and pull strokes. The saw's additional stiffness helps prevent the saw from buckling on the push stroke.

Because felling saws are flexible, they do not make a good bucking saw or a general all-around utility saw. The bucking saw is recommended as the standard saw for most trail and construction applications.

Saw Grinds

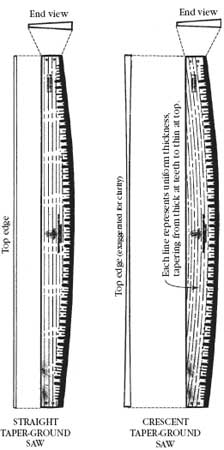

Historically, the sides of a saw were ground using one of three methods. Each method affected the thickness of the saw. These grinding methods are flat, straight taper, and crescent taper.

Flat Ground—On a flat-ground saw, the metal's thickness is the same throughout. Saws manufactured today are flat ground.

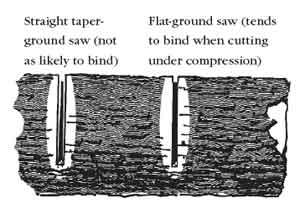

Straight Taper Ground—Straight taper-ground saws have an advantage over a flat-ground saw because the saw is thinner at the back than at the center (figure 5-4). The back of the saw has more clearance, reducing binding.

Straight taper-ground saws require less set. Set is the cutter tooth's offset from the plane of the saw.

Figure 5-4—Comparison of cuts made by straight

taper-ground and

flat-ground saws.

Crescent Taper Ground—The best vintage saws were crescent taper ground (figure 5-5). Early saw manufacturing companies used different trade names for crescent taper-ground saws. The names included: crescent ground (Simonds), improved ground (Disston), and segment ground (Atkins).

Figure 5–5—Comparison of straight taper-ground and

crescent taperground

saws. Neither is manufactured today.

Today's saws are flat

ground.

Crescent taper-ground saws offer the most clearance in the kerf of any of the grinds. These saws require the least amount of set, allowing the narrowest kerf. The thinnest part of a crescent taper-ground saw is at the back center.

How a Saw Cuts

A saw functions like a series of knives (teeth) making simultaneous parallel cuts and releasing the wood between them.

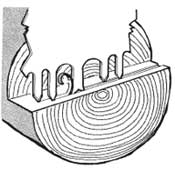

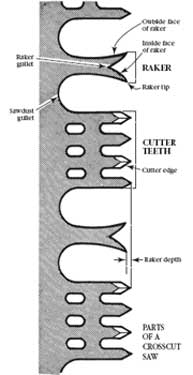

Cutter Teeth—All saws, regardless of the tooth pattern, are made up of two rows of cutting edges. The saw releases wood fibers on each side of the kerf as it passes through a log (figure 5-6).

Cutters work best in brittle, seasoned wood. The weakened fiber is easily removed.

Figure 5-6—How a crosscut saw cuts.

Rakers—Wet or green wood is hard to remove from the kerf because it is resilient. Even when the fiber is dislodged, it clogs a saw's cutter teeth.

A special kind of tooth, the raker, allows the cutter teeth to work more effectively with less effort. Even though the rakers do not sever fiber, they do perform the other two functions of saw teeth: breaking loose the cut fiber and removing it from the log. Rakers remove material whether the saw is being pushed or pulled.

Gullets—Wood fiber that has been severed must be stored by the saw while it is moved through the kerf and out of the cut. This storage area (the largest space between cutters or groups of cutters) is called a gullet.

The gullet must be large enough to store all the shavings until the gullet clears the log and the shavings fall free.

The gullets (figure 5-7) determine the proper length of saw for a given application. Example: A gullet in the middle of a 3-foot log must travel 1 ½ feet to clear its shavings on either side. At the minimum, a 6 ½- or 7-foot saw would be needed to provide this travel.

Figure 5-7—The configuration of the teeth of a crosscut

saw. This is

the perforated-lance tooth pattern.

Tooth Patterns

For centuries, only the plain tooth (or peg tooth) pattern was used. Modifications to the plain tooth pattern were developed to make the work easier. We will discuss six patterns: the plain tooth, the M tooth, the Great American tooth, the champion tooth, the lance tooth, and the perforated lance tooth (figure 5-8).

Plain Tooth (Peg Tooth) Pattern—This pattern just includes cutter teeth. It is best used for cutting dry, very hard, or brittle small-diameter wood. Many bow saws and pruning saws use a plain tooth pattern.

M Tooth Pattern—This is the second generation of saw tooth patterns. The tooth pattern consists of pairs of teeth separated by a gullet. The outer edges of the teeth (the legs of the M) are vertical and act like rakers. The inside edges of the M are filed to a bevel, making a point. This tooth pattern is best suited for cutting dry, medium to hard woods.

Great American Tooth Pattern—This tooth pattern, three teeth separated by a gullet, is designed to cut dry, medium to hard woods. A special file is used to file these saws. The file can still be purchased today and is called a crosscut file or a Great American file.

Champion Tooth Pattern—This pattern is especially popular in the hardwood regions of North America. It consists of two alternately set cutter teeth and an unset raker with a gullet between them. The cutters are wider and more massive than the lance tooth pattern, allowing heavy sawing in extra hard, dry, or frozen wood. The larger teeth are sharpened in more of an almond shape rather than the pointed shape of a lance tooth.

Lance Tooth Pattern—For many years, the lance tooth pattern was the standard for felling and bucking timber in the American West. It consists of groups of four alternately set cutters separated by an unset raker with gullets on each side. The lance tooth pattern is best suited for cutting soft green timber, especially fir, spruce, and redwood.

Perforated Lance Tooth Pattern—This tooth pattern is considered a general utility pattern that can cut all but hard and frozen wood. It consists of groups of four alternately set cutters separated by an unset raker with gullets on each side. The bridges between the teeth form the perforations that give the pattern its name. These bridges strengthen the teeth and reduce chatter when the saw is used to cut harder wood.

Figure 5-8—Saw tooth patterns.

Saw Handles

The handle's position on the saw affects the saw's efficiency. Changing either the arm and hand position, or the handle position, changes the delivery of force to the saw.

Types of Saw Handles

Handles may be fastened permanently to the blade with rivets. Removable handles may be fastened to the blade with a steel loop or with a pinned bolt and wingnut assembly.

Quality saw handles are often hard to find. Handles must be strong and must not allow movement between the handle and the blade.

Loop Style—The loop-style handle is a common design. Most of these models have a metal loop running up through a hardwood handle to a nut, which is inside the handle (plug nut) or is part of a cap at the end of the handle. The loop design allows the loop to be slipped over the saw blade. When the wooden handle is turned, the loop tightens around the saw. These models do not use the saw handle holes. Most saws have a notch or a valley that the bottom of the loop rests in.

Because these saw blades must have a notch for the loop, they do not have teeth all the way to the end of the blade.

Pin Style—The pin-style handle design—the most common— uses the handle holes in the saw blade.

The climax-style handles were the most common pinstyle design. Even today, they appear on some modern two-person crosscut saws.

Perhaps the most common vintage saw handle used today is the Pacific Coast model of the pinstyle design. It has a finger guard with a groove to accept the saw blade and two cast flanges. The ½-inch-diameter rivet pin passes through a hole in the wooden handle. It is secured with a heavy wingnut.

Supplementary handles are used on one-person crosscut saws. The handle can be placed at the end of the saw for an additional sawyer or directly in front of the D-shaped handle when a single sawyer wants to use both hands.

Handle Installation and Maintenance

A one-person saw has a fixed D-shaped handle with additional holes on the top of the saw to attach a supplemental handle. Many two-person crosscut saws (usually bucking saws) have two holes on each end for handles. Moving the handle from the lower hole has the same effect as moving the hands several inches up the saw handle. With the handle in the upper hole, a push stroke applies more downward force on the saw, causing the teeth to sink deeper into the wood. The deeper cut requires more force on the pull stroke. A slight upward force is applied to the saw, making it easier to pull.

The wooden handles on crosscut saws are usually selectgrade hardwoods 1¼ inches in diameter and about 14 inches long. When the handle is not on the saw, the handle needs to be kept away from sharp edges that could nick or cut it.

Saw Maintenance

The maintenance topics discussed in this section are for the crosscut sawyer. Some topics, such as saw filing, are included just to provide an overview during training. An experienced saw filer should do the filing. The Crosscut Saw Manual (7771-2508-MTDC, revised 2003) by Warren Miller is an excellent resource for more information on saw maintenance and filing.

Cleaning the Saw

Saws need to be clean to function effectively. Clean saws at the end of the day before storing them.

Lubricants and Solvents—Types: Petroleum-free lubricants, such as canola oil, are available commercially. Solvents with citrus-based ingredients, such as Citrosqueeze, also are recommended.

Functions: Saw teeth do not need to be lubricated as they cut. The friction of the saw teeth against the kerf keeps the teeth reasonably clean. However, resin deposits on the lower part of the teeth and in the saw gullets produce drag. Lubricants can soften these deposits and help remove them.

Cutting in extremely wet environments or during a hard rain can cause wood fibers to swell. In these conditions, a petroleum-free lubricant can help reduce drag. Clean the saw with an environmentally acceptable solvent at the end of each day and apply a thin coat of petroleumfree lubricant.

Applying Lubricants: Open containers waste lubricants. Squeeze bottles allow the sawyer to direct a stream of lubricant onto the saw's surface. On the pull stroke, the sawyer keeps one hand on the saw handle and applies the lubricant with the other, putting the bottle down before the next push stroke.

Removing Rust: Rust probably does more damage to saws than anything else. Remove light rust using steel wool. Use a pumice grill block to remove rust that is too heavy to be removed with steel wool. A liberal amount of cleaning solution will keep the block's pores open.

To remove heavier rust, use an ax stone. Always use a liberal amount of cleaning solution. NEVER use a dry stone on the saw blade.

As rust and other deposits are removed, you will see imperfections in the saw blade. Spots that are shinier than the rest of the saw are high spots. Spots that are duller than the normal saw surface indicate low spots. A high spot on one side of the blade usually produces a low spot on the other side. These kinks or bends need to be hammered out by an experienced saw filer.

Do not apply too much pressure on the cutter teeth because you can remove metal from the set and reduce tooth length.

A wire brush can be used to remove loose rust and scale. NEVER use a power sanding disk on a saw blade.

Removing Pitch: A saw that is well cared for will not rust, but it will develop pitch deposits during normal use. Some pitch can be removed with a citrus-based solvent as the saw is being used by allowing the saw's motion to scrub away the buildup. However, pitch still can be deposited on the saw. Pitch buildups can be removed at the end of the day with steel wool and a cleaning solution.

Using Cleaning Solutions: Limit the use of harsh chemicals for cleaning saws. Wear the proper personal protective equipment and know how to use the cleaning solutions safely. Check the material safety data sheet if you are unfamiliar with the hazards of using and storing a particular product. A number of citrus-based cleaners on the market are effective and safe.

Naval gel can be applied to remove heavy rust and scale. Use only as directed, with adequate ventilation. This product stops the chemical reaction of the rust.

Checking for Straightness

Check the saw periodically for straightness. A saw should be checked if it receives any harsh treatment during transportation or use. A saw that is not straight can buckle on the push stroke. The narrower, lighter felling saws are more prone to buckling.

Using Straightedges—Remove the saw handles and hang the saw vertically from one of its handle holes.

Saw filers usually have straightedges made especially for this work. You will need a pair of straightedges. Two combination square rules can be used. Before using the straightedges on the saw, hold them together and make sure they maintain contact along their entire length. You should not see light between them when you put them together and hold them up to a light source.

Straightedges work by allowing you to feel the difference in resistance between the saw and the straightedge as the straightedges are twisted back and forth over the saw's surface. The straightedges are moved as a pair with the saw between them. You will feel increased drag on the ends of the straightedge on the side of a saw with a depression. On the other side of the saw, the straightedge will pivot easily on the corresponding bump. Even resistance on both straightedges reflects a straight saw that does not have any kinks, bends, or bumps.

If you find any major irregularities, report them to the person who files your saws.

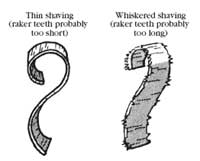

Testing the Saw—Testing determines whether a saw cuts straight, runs smooth, and produces long, thick shavings. The saw should produce shavings and not sawdust. The longer and more abundant the shavings, the better the saw is performing. Green logs produce longer shavings than dry logs. The shavings should be long and thick with smooth edges. If the edges of the shavings have whiskers or irregularities, the rakers are probably too long. If the shavings are paper thin, the rakers are too short (figure 5-9).

Figure 5-9—Examine shavings to identify

sharpening problems.

Does the saw cut straight? Cut far enough into the test log to determine whether the cut is perfectly straight. If the saw consistently pulls to one side through no fault of the sawyer, the saw needs additional maintenance.

Sometimes a sawyer standing in an awkward position can put a twist or bend on the saw. A saw will not cut straight if it is kinked or bent.

Too much set on one side of the cutters can cause the saw to pull to that side. If a saw has been sharpened improperly, the teeth may be longer on one side than the other. The saw will pull to the side with the longer teeth.

Does the saw run smooth? Look for a saw that does not chatter or seem like it is jumping through the log. The saw also may feel like it alternately catches and releases. A smooth-running saw seems to cut effortlessly.

Smoothness is most associated with the rakers. If a saw feels like it is snagging the wood, it is probably because one or more rakers have been filed incorrectly.

Inconsistent set in the teeth also can produce a jumpy saw. Look at the walls of the cut. The cut surfaces should be smooth.

NEVER field sharpen or touch up dull cutters; doing so shortens the teeth, compounding the problem.

A sawyer cannot do anything to fix a saw that is running rough. A qualified saw filer will need to make the necessary adjustments.

Brief Overview of Saw Filing Procedures—This overview will not teach a student to file a crosscut saw. But it will allow the student to understand the skill and labor required to sharpen and recondition a crosscut saw. Specialized tools are needed to file saws. Filing must be done by a qualified filer in a saw shop.

The crosscut saw may be the most precise tool that a woods worker uses. An experienced filer setting teeth can feel the difference between a 0.013-inch and a 0.012- inch set. That means the filer is making a 0.0005-inch judgment.

Saw Vises and Tools: A filer needs to work in a welllighted location with a wooden vise to hold the saw.

Straightening: Straightening is an art in itself. The filer must move the metal carefully by hammering the blade on an anvil.

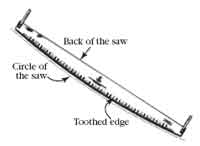

Jointing: After the saw has been cleaned and straightened, jointing is the first step in sharpening. A tool called a jointer holds the file. The points are filed off the cutter tips so that each of them lies on the circle of the saw (figure 5-10).

Figure 5-10—Circle (or arc) of the saw.

Fitting Rakers: The raker gullet is shaped using a triangular file. The raker is lowered and checked with a pin gauge, which establishes the exact clearance below the cutters.

Tooth Pointing: Each tooth is sharpened to a point. The filer has the option to make the bevel suit the type of wood the saw is being used to cut.

Setting Teeth: The teeth need to be set so they lie directly behind one another. The filer puts equal set in all the teeth by hammering the points over a beveled hand anvil. The set is checked using a tool called a spider.

Storage—Whether they are stored at a backcountry guard station or at a unit's warehouse, crosscut saws need to be stored properly.

Long-Term Storage: Store crosscut saws straight. Remove the handles and store the saws in a dry location.

NEVER store a saw flat on a metal surface. It is best to hang a saw from a nail through a handle hole. Although the saw can lie horizontally if it is supported along its entire length, items may be dropped on the saw, damaging it. During long-term storage, oil will bleed into the saw's wooden handle if the saw is lying flat.

Apply a coating of heavy oil or grease diluted with solvent before storing a saw. Wear appropriate gloves when applying the oil.

NEVER lean a saw against a wall where it could develop a bend.

NEVER leave a saw bent around a fire pack.

DO NOT store a saw in a sheath or with a guard on it. Rubber-lined fire hose is particularly bad because it traps moisture next to the saw's teeth.

DO NOT hang a saw where animals or people could be injured by the saw's unsheathed teeth.

DO NOT store saws on top of one another. When the unsheathed saws rub against each other, the saws can be damaged.

Storage in the field: Saws need to be wiped clean and rubbed with canola oil or another environmentally sensitive lubricant before you leave them in the field. Choose a storage location out of human sight and away from game trails. If saws are being left overnight, they can be laid under a log with the teeth pointed in.

Remove the saw handles and sheaths. Bears tend to gnaw on wooden handles. Rodents chew on leather straps and anything that has salt on it. Leave nothing but the metal parts in the field. If you are storing a saw longer than for just one night, hang it.

Saw sheaths: Sheaths protect the saw and prevent it from causing damage or inflicting injury. Saws should be sheathed as much as possible unless they are being used or are in storage. Wear gloves when removing or replacing a saw sheath.

A length of old firehose that has been split makes one of the best crosscut saw sheaths. Wipe the hose's rubber inner lining with an oily rag to repel water and reduce the possibility that moisture in the sheath will cause the saw to rust.

Attach the firehose to the saw using parachute cord or Velcro closures. To install the hose sheath, begin by rolling it inside out (rubber side out). Turn the saw so its teeth face up; unroll the hose down the saw, covering the teeth.

Some sawyers sandwich the saw between two rectangular pieces of plywood. The saw's handle holes are placed over pins at each end of one of the pieces of plywood, securing the saw.

Transporting Saws—Saws must be transported in a way that protects them from being damaged, from injuring people or livestock, and from damaging property and equipment.

Saws are difficult to transport because they are long and flexible. Vintage saws are bent to make them easier for hikers or packstock to carry. Saws can be delivered by parachute. Modern saws SHOULD NOT BE BENT. The softer metal will hold the bend.

Because saws may be taken by boat, plane, helicopter, truck, dog sled, or packstock, or be carried by a hiker during different legs of a journey, several types of protection may be needed to get a saw to the work site. Sheaths should always cover saws when they are being transported.

Saws get hot in the sun. Use gloves to handle a saw that has been lying in the sun.

Boats: If a saw is being transported in an open skiff, remove the saw's handles and place the sheathed saw on top of the other cargo. On many boats, the place that is the most out of the way is along the gunwales. Open boats can take on a lot of spray. Saltwater spray can cause rust. ALWAYS coat the saw with canola oil or another environmentally sensitive lubricant before transporting it. Once the saw is on land, remove the sheath and rinse off any salt with a good freshwater bath.

Saws transported on kayaks are best secured to the bow where they can be seen. In canoes, carry saws in the center on the floor. Transport the saw without handles in a rubber-lined hose sheath. Secure the saw by tying parachute cord through the handle holes. Be sure to remove the sheath and dry the saw after arriving at your destination.

Aircraft: In small aircraft, the saw's handles can get in the way. If a saw's handles must be removed to bend the saw into a loop, wire MUST be strung through the handle holes to secure the saws. DO NOT string parachute cord or any other nonmetallic material (including nylon ties) through the handle holes to secure the saw. Jostling during the flight could cut nonmetallic materials, allowing the saw to spring to full length. The same considerations apply when saws are carried in helicopters.

Helicopters can transport saws as an external load. Use care when packing saws that are carried as sling loads by helicopters. One way to reduce breakage is to carefully bend the saw around a box. Place the box in the middle of the sling bag with the saw's ends down. Stack other materials around the saw.

Vehicles: When transporting crosscut saws in a pickup truck, lay the sheathed saw flat on the bed of the truck. Don't place heavy tools on top of the saw.

Dog Sleds: In some areas, saws are transported by dog sled. If you do not expect to use the saw to clear trails during the trip, sheathe the saw and place it on the bottom of the sled. If the saw may be needed for trail work, place it along one side of the sled where it will be easier to reach.

Packstock: Take extra care when carrying a crosscut saw on packstock. Select the gentlest animal to carry the saw. Put that animal in the lead where you can see the saw easily.

The handles on a two-person saw shall remain attached. Sheathe the saw with firehose and wrap the saw in a mantie with the handles exposed and secure. Bend and place the saw over the animal with the teeth facing to the rear (figure 5-11). Tie the saw handles down to the latigo or the cinch ring. Tie the center of the bowed saw to the packsaddle and not just to the load. When the saw is fastened on top, it is more likely to stay on top of the animal if the rope on either side becomes untied. Finish the packing job by using the cinch lash to tie the saw to the rest of the load. That way, the saw is unlikely to come loose.

Figure 5-11—Bend and place the saw over the

animal with the teeth

facing to the rear.

One-person saws can be transported on riding stock in a leather or canvas scabbard (similar to a rifle scabbard). A piece of hardwood protects the scabbard from the saw's teeth.

Hikers: Saws should be sheathed when you are hiking to the job site. The person carrying the saw should be the last person in line.

Two-person saws should have the rear handle removed. If the handle is left on, it can snag on branches.

The saw can be carried on your shoulder with the teeth facing outward. AVOID carrying the saw with the teeth pointing inward. Carry the saw on your downhill shoulder so you can throw it off if you slip or fall.

A vintage saw can be bent around a pack if it is being carried for long distances. Usually, both handles are left on to secure the saw in its bent position.

Saw-Related Equipment and Tools

Axes

Single-bit axes need to be heavy enough (3 to 5 pounds) to drive plastic wedges into the trees being felled. The back of the ax (poll) should be smooth, have rounded edges, and be free of burrs to minimize damage to wedges. Pulaskis should never be used to drive wedges.

Always remove branches, underbrush, overhead obstructions, or debris that might interfere with limbing and chopping. Do not allow anyone to stand in the immediate area. Make sure workers know how far materials may fly. Protect all workers against flying chips and other chopping hazards by requiring them to wear the appropriate PPE.

Always position your body securely while working with a tool. Never chop crosshanded; always use a natural striking action. Be alert when working on hillsides or uneven ground. If you cut a sapling that is held down by a fallen log, the sapling may spring back. Be alert for sudden breakage. If you do not have a need to cut something, leave it alone.

Never use chopping tools as wedges or mauls. Do not allow two persons to chop or drive wedges together on the same tree. When chopping limbs from a felled tree, stand on the opposite side of the log from the limb being chopped and swing toward the top of the tree or branch. Do not allow the tool handle to drop below a plane that is parallel with the ground unless you are chopping on the side of the tree opposite your body.

If the cutting edge picks up a wood chip, stop. Remove the chip before continuing. To prevent blows from glancing, keep the striking angle of the tool head perpendicular to the tree trunk.

Wedges

The use of wedges differs when cutting with a crosscut saw rather than a chain saw.

Wedges are essential tools for safe felling and bucking. They provide a way to lift the tree, preventing the tree from sitting back when it is being felled. A wedge must be inserted into the back cut as soon as possible. Wedges also reduce binds on the saw when bucking.

Select the correct wedge for the job. The proper type, size, and length of a wedge vary, depending on the wedge's use. The size of the tree being felled or the material being bucked determines the size of the wedge that will be needed. If the wedge is too small, it may be ineffective.

Most wedges are made out of plastic or soft metal, such as magnesium, and come in different sizes. Use plastic wedges in both felling and bucking operations to prevent damaging the saw if it contacts the wedges. Plastic wedges do not split easily, and their textured surfaces provide additional holding power in the wood, helping to prevent the wedges from backing out when they are being driven.

Although all wedges can be stacked (used one on top of the other), wedges may slip sideways if each wedge is not driven squarely. Always drive wedges by striking them squarely on the head. Drive them carefully to keep them from flying out of the cut.

Newer wedge designs include rifled wedges. These wedges have a pair of grooves on one side and rails on the other side. This design helps the wedges stay in place when they are stacked on each other.

The two basic types of wedges used in sawing are single (figure 5-12) and double (figure 5-13) taper. The tripletaper wedge (figure 5-14) has a thin angle at the entry, an intermediate angle through most of the body, and a steeper angle near the top. This design allows a shorter wedge to produce as much lift as a longer single-taper wedge and works well on small-diameter trees.

Figure 5-12—A rifled

single-taper wedge

is

designed to provide lift

when a tree is felled.

It

can be stacked with

additional rifled singletaper

wedges. The rifling

helps keep the wedges

aligned and stacked as

they are being driven.

Figure 5-13—Doubletaper

wedges are designed

to reduce bind.

Figure 5-14—Triple-taper

wedges allow a

short wedge

to provide as much lift as a

longer wedge but require

more force

to drive.

Check wedges daily or before each job. Do not use cracked or flawed wedges. Wedges that are damaged need to be cleaned up before they are used again.

Recondition heads and the tapered ends when grinding wedges to the manufacturer's original shape and angle. Wear eye protection and a dust mask when grinding.

Repair any driving tool or remove it from service when its head begins to chip or mushroom.

Carry wedges in a wedge holster or other container, not in the pockets of clothing.

Splitting Wedges—Splitting wedges are made of steel. Magnesium wedges should not be used to split wood.

Steel wedges with smooth faces sometimes rebound out of cuts when they are driven. Smooth faces can be roughened up with a cold chisel. Most steel wedges have shallow grooves or depressions below the wedge face. Wood fills these voids and reduces the chance that the wedge might back out.

Wedges must be set firmly before they are driven with a double-jack sledge hammer.

Wedges to reduce bind or split wood are double-tapered, meaning that each of the broad faces taper equally from the center. When such wedges are driven, the force is equal on both sides, causing the wood to move equally.

Lifting Wedges—Lifting wedges are an inclined plane, tapered on just one face.

Lifting wedges exert force in the direction of the inclined plane. Two wedges can be stacked one on top of the other to produce an even lift. Lifting wedges have many applications. They can be used to tighten, pry apart, or move materials.

Exerting a force in one direction can be valuable. The sawyer may need to exert a force in one direction when getting a saw unstuck or when removing a chunk of log if a carelessly placed compound cut gets bound up.

Plastic or steel wedges can be bought with a single taper. These wedges often have a groove on the flat side to increase holding power. The lifting or moving takes place on the smooth side that serves as the inclined plane.

Peaveys and Cant Hooks

The blacksmith Joseph Peavey invented the peavey (see figure 3-23a). Both the peavey and the cant hook (see figure 3-23b) use a curved metal hook on the end of a straight handle to roll or skid logs. A peavey has a sharp pointed spike at the lower end, while a cant hook has a tow or lip. Most peaveys and cant hooks come with a duckbill hook that is a good all-around style. Peaveys and cant hooks have hickory handles that are from 2 to 5½ feet long.

Peaveys are used almost exclusively in the woods. Peaveys are handy for prying logs up onto blocks to keep the saw from pinching while bucking. The cant hook is used primarily to roll logs.

- Keep the handles free of splinters, splits, and cracks.

- Keep points sharp.

- Keep your body balanced when pushing or pulling the pole.

- Grip the handle firmly; do not overstress it.

- Place a guard on the point when the tool is not in use.

Underbucks

Underbucks help hold the saw in position when the saw is cutting from underneath the log. They also act as a fulcrum. A good sawyer can cut as fast—or faster— from underneath a log as from the top. When a sawyer is cutting from underneath, a downward pressure on the underbuck handle forces the saw up into the log. The sawyer does not have that mechanical advantage when cutting from the top.

Types of Underbucks—Axes are the most common type of underbuck. Axes used for underbucking should have a 36-inch wooden handle that has been slightly modified. Cut two series of three notches on one side of the handle about 6 inches from the end, leaving room (below the notches) for your gripping hand when you use the ax for chopping.

The three notches, placed about an inch apart, allow the sawyer to more accurately line up one of the notches with the cut. The notches should be 30 to 45 degrees off perpendicular to allow room for the saw between the ax handle and the log.

Some mechanical underbucks attach to axes; others are sheaves that fit over an ax handle; and others are standalone tools. Most underbucks have a groove or roller on the end to serve as a guide for the back of the saw (figure 5-15). This groove or roller needs to be adjusted properly to align the saw cut.

Figure 5-15—A mechanical underbuck helps hold the saw

up when

cutting from the underside of the log.

The MTDC tech tip, Crosscut Saw Underbucking Tool (0223-2330-MTDC), shows how to fabricate a lightweight underbuck that features a 2-inch clamp with a shielded steel pulley. It attaches to an ax handle.

Bucking Preparation and Techniques

Safety Considerations

The same principles apply whether a crosscut saw or a chain saw is used for bucking, but the sawyer is exposed to risks longer during crosscut saw operations. Great care needs to be taken when bucking.

Situational Awareness:

- Never buck a tree that exceeds your ability.

- Consider overhead hazards.

- Establish good footing.

- Swamp out bucking areas and escape routes.

- Anticipate what will happen when the log is cut.

- Plan the bucking cut carefully after considering:

- Slope. People and property in the cutting

zone can be in the path of rolling logs.

- Tension. Spring poles are trees under tension.

- Compression. Falling or rolling root wads

are unpredictable when compression is released.

- Rocks and foreign objects under the log. The log will have a tendency to roll, slide, or bind. Broken off limbs hidden underneath the log can roll up and strike the sawyer.

- Slope. People and property in the cutting

zone can be in the path of rolling logs.

Bucking Sizeup

Three major hazards are associated with bucking.

Spring Poles—Spring poles are generally small-diameter trees or brush that are pinned under larger trees (figure 5-16). Because the trees or brush are still rooted, when they become pinned, they are under tension. If this tension is undetected, when the spring poles are cut, they can spring back with tremendous force and strike the sawyer. Cut a spring pole only when necessary.

Determine what will happen when the spring pole is cut. A crosscut saw is not used to release a spring pole unless the pole is very large. Normally an ax, pruning saw, or pulaski is used.

Figure 5-16— Look for spring poles. They can release

and cause

accidents.

- To remove spring poles properly, begin by relieving

some of the tension in a controlled manner. To do this,

stand back at a safe distance and make a series of shallow

cuts about one-half inch apart on the underside of

the spring pole. Be careful not to cut too deep. During

each cut, as soon as you detect movement, remove the

saw and begin the next cut. Four to six cuts on the

bottom of the spring pole should be sufficient.

- The release cut is made from the top, about ½ inch past the end of the series of cuts on the bottom and on the piece that is going to fall to the ground. Be sure you are clear of the piece that will be released.

Suspended Logs—Cutting a suspended log is a singlebuck operation. Often only one side is safe or has adequate footing for you to make the cut.

If you are standing on blowdown where several trees are jackstrawed in different directions, carefully evaluate the sequence in which trees should be removed. Generally, REMOVE THE BOTTOM LOGS FIRST. This practice reduces the chance that top logs or other material will move.

It might not be possible to remove all suspended trees with a saw. Only take out the ones that can be removed safely. Other suspended trees can be removed with winches or explosives, if necessary.

Suspended logs often roll when they are released. Be sure the log has a safe path to travel. Logs may ricochet off other objects, making their path unpredictable. BE SURE no snags or other weak trees are in the log's path. They could snap if they were struck by a rolling log. Fell snags or weak trees first, if they can be felled safely.

Unsound Wood—Unsound wood can crack or break without warning. It can be hazardous because it is unpredictable. Logs may be sound in one area and rotten in other areas. Examine ends of logs for signs of rot. Observe the color of shavings the saw is producing. Dark shavings indicate rot. Rotten wood doesn't hold wedges well, making them ineffective. Because rotten logs may hold more moisture, crosscut saws tend to load up, increasing the need to use wedges to keep the kerf open.

Planning the Cut

Can the log be safely bucked with the sawyer's skills and equipment? Sawyers should not feel pressured to perform any task that is above their ability. Ask other crew members to size up the situation silently. Discuss findings afterward.

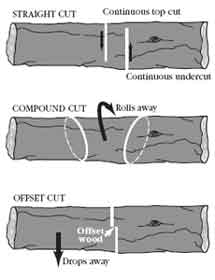

Types of Cuts—The three basic types of cuts are straight cuts, compound cuts, and offset cuts. We will describe each type of cut and its usual application (figure 5-17).

Figure 5-17—Three basic cuts: straight, compound,

and offset.

A straight cut is made through the log from one side. It can be performed by single or double bucking. It also can be cut from underneath the log by a single sawyer (using an underbuck).

A compound cut is placed at an angle less than perpendicular to the log and angled so that the bottom of the cut slopes toward the part of the log that is being removed. This cut typically is used when clearing a large log that is across a trail. Two cuts need to be made and the severed chunk of the log has to be removed.

The offset cut is placed so that the bottom underbucking cut DOES NOT MATCH UP exactly with the top cut. This kind of underbucking operation is used when a log is suspended and will drop free when severed. Once the top cut has been made, a single sawyer installs a mechanical underbuck or selects one of the grooves cut into the ax handle (a groove about ½ inch toward the ax head from the top kerf). The ax head is always secured to the side of the log that won't move when the log is cut.

The small amount of offset wood acts like the holding wood left when trees are felled. In felling, the holding wood keeps the tree from kicking back. In underbucking, the offset wood prevents the severed log from damaging the saw when the log drops. If the offset wood is severed, control is lost. If the cuts meet, the log will want to carry the saw with it when the log drops. Because the ax handle supports the saw, the saw's force can break the ax handle. The saw may fly upward, possibly injuring the sawyer, or bending, kinking, or snapping the saw.

Determining Binds—Understanding directional pressures, or binds, is important. These binds determine bucking techniques and procedures.

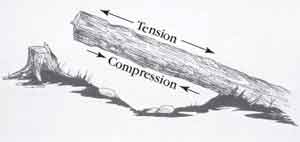

Landforms, stumps, blowdown, and other obstacles that prevent a log from lying flat cause binds. Binds are different directional pressures exerted in different areas of the log. The tension area (figure 5-18) is the portion of the log where the wood fibers are being stretched apart. In this portion of the log, the saw's cut (kerf) opens as the cut is made. In the compression area, the wood fibers push together. In this portion of the log, the kerf closes as the cut is made.

Figure 5-18—The log is being pulled apart by tension

force and pushed

together by compression force. The tension and

compression areas

are on opposite sides of the log.

It is extremely important to determine what will happen to the log when it is cut. Inspect the log for all binds, pivot points, and natural skids. Various bucking techniques can be used to lower a suspended tree to the ground.

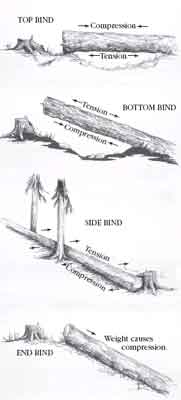

The four types of bind are: top, bottom, side, and end (figure 5-19). Normally, logs have a combination of two or more binds:

Top bind: The tension area is on the bottom of the log. The compression area is on the top.

Bottom bind: The tension area is on the top of the log. The compression area is on the bottom.

Side bind: Pressure is exerted sideways on the log.

End bind: Weight compresses the log's entire cross section.

Figure 5-19—There are four types of binds. A log can

have a combination

of two or more binds.

Determine Bucking Locations—It is best to start bucking at the top of the log and work toward the butt end, removing the binds in smaller material first. Look for broken limbs and tops above the working area. NEVER stand under an overhead hazard while bucking.

Look for spring poles—Look for small trees and limbs bent under the log being bucked. They may spring up as the log rolls away. If you can safely do so, cut them off before the log is bucked. Otherwise, move to a new cutting location and flag the hazard. Anticipate the spring poles' reactions.

Determine the Offside—The offside (figure 5-20) is the side the log might move to when it is cut, normally the downhill side. Watch out for possible pivots. Clear the work area and escape route. Establish solid footing and remove debris that may hinder your escape.

Figure 5-20—Determine the offside (usually the downhill side)

and

stay clear of that side when you are single bucking.

Cut the Offside First From a Safe Position—If possible, make a cut about one-third the diameter of the log. This allows the sawyer to step back from the log on the final cut.

Watch the Kerf To Detect Log Movement—Position yourself so you can detect a slight opening or closing of the kerf. There is no better indicator of the log's reaction on the release cut. If the bind cannot be evaluated, proceed with caution. It may be necessary to move the saw back and forth slowly to prevent the saw from getting bound as pressure closes the kerf. Cut only far enough to place a wedge. Continue cutting. Watch the kerf. If the kerf starts to open, the log has a bottom bind. If the kerf starts to close, the log has a top bind (figure 5-21).

Figure 5-21—Watch the kerf for movement that will

indicate a bottom

bind (kerf opens) or top bind (kerf closes).

Reduce the Remaining Wood—Visually project the kerf's location to the bottom of the log. Cut a short distance into the log along this line to reduce the amount of wood to be cut on the final cut. Be prepared for kickback.

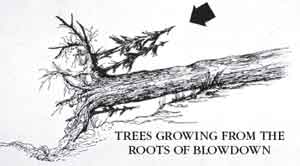

Hazards of Bucking in Blowdown—Strong winds uprooted trees in areas of blowdown. At any time while the bucking cuts are being made, the roots can drop back into place or roll in any direction. Avoid standing directly behind or downhill from the roots.

Small trees growing on the roots of blowdown (figure 5-22) could be forced into the sawyer's position if the roots drop or roll. Cut the small trees off first. Some of the trees' limbs may be preventing the roots from rolling. Don't cut off those limbs.

Figure 5-22—Small trees growing on the roots

of blowdown

(arrow) can move if the roots drop or roll.

Points to Remember

- Size up your situation thoroughly.

Identify the hazards and establish

your escape routes and safety zones.

- Use objects such as rocks, stumps (if they are tall

enough), and sound, standing trees with no overhead

hazards for protection in the event the tree

springs sideways toward you when you saw the

release cut.

- Eliminate other binds before removing any single

section of log that may be under stress. Angled

bucking cuts, wide on top and made on the offside,

allow a single section of log to be removed. Angled

cuts let the bucked section of log roll away from the

rest of the log. Buck small sections that will be easy

to control when they begin moving.

- Reevaluate your situation constantly, because binds

and log movement will change as you cut.

- Approach a cutting operation only from the uphill

side. Warn workers who are working in and below

an active cutting area. Allow workers time to move

to a safe area. Verify their safety visually and verbally.

Announce when a bucking operation has

been completed.

- Sever all logs completely as you buck. Partially bucked logs are hazards and should be marked with flagging.

Single-Bucking Techniques

New sawyers should master the skill of single bucking before learning double bucking. If new sawyers can handle a long two-person saw alone, they have mastered the principles of keeping the saw running smoothly without buckling. Thinner, lighter felling saws are hard for all but the most experienced sawyers to use for single bucking. The stiffer, heavier bucking saw is easier to push during single-bucking.

The reasons to single buck are:

- The sawyer starts out double bucking and needs to

finish the cut from one side because of safety considerations

or log movement.

- The log is too large for the length of the saw.

- The sawing sequence starts or ends with underbucking, which can be done only by a single sawyer.

As a general rule, the saw needs to be twice as long as the log's diameter plus 6 inches. To illustrate the problem, imagine trying to cut a 4-foot-diameter log with a 7-foot saw. If the center raker and adjoining gullets are in the center of the log, each sawyer needs at least 2 feet of free blade so the center gullets will clear the log. With a 7-foot saw, the shavings would never be removed from the gullets in the center foot of the saw. On each stroke, the gullets would pick up more shavings. As the gullets filled, the saw would work harder and bind, especially if the wood was green and pitchy. Usually, sawyers can't run the saw all the way to the handles without having their hands drawn into the bark.

A single sawyer can take off the handle at one end of the saw. That end of the saw can be drawn into the log, allowing the shavings to be removed from the gullets.

When making compound cuts, the length of the cut determines how long the saw needs to be. The saw does not work as efficiently in a sloping cut or a compound cut. The more angle that is placed on a compound cut, the less effective the saw is working. Compound cuts can make for some hard sawing.

Single Bucking with No Bind: Top Cutting—

- Lay the unsheathed saw on its side over the log to be

bucked. Sprinkle lubricant on both sides of the saw.

- Hold the saw in the dominant hand and guide the back

of the saw with the other hand for a few strokes until

the saw is set in the kerf.

- Insert wedges as soon as possible, driving them snug.

Take care not to hit the saw.

- Lubricate the blade as needed just before the push

stroke. On a smaller log, the sawyer may be able to

lubricate the far side of the saw just before the pull

stroke. Be sure to lubricate both sides of the saw blade

equally.

- As the cut is ending, use only the teeth at the end of the saw blade. This technique prevents the log from damaging the production cutters near the center of the saw when the log rolls or pinches the saw.

Single Bucking with Top Bind: Underbucking Required—

Underbucking is used when the log has a top bind and you can get under the log. The first cut must be started from the top because the top of the log is under compression. If the compression is not corrected, the kerf may close and pinch the saw.

After you have inserted the wedges and driven them snug, continue cutting down from the top, leaving enough uncut wood to support the log's weight. Because the top of the log is under compression, the bottom is under tension. The more compression you relieve, the greater the tension on the bottom of the log. The log will start to equalize this pressure by exerting pressure on the wedges. If you use two or more wedges spaced at the 10 and 2 o'clock positions, you can spread the force over a large area. If only one wedge is used at the 12 o'clock position, all the energy is directed to that relatively small area.

Remove the saw from the top cut and prepare to finish the cut from the bottom by underbucking. A log or rock can be placed under one side of the cut to support the log. That way, the log will be less likely to carry the saw to the ground when the cut is completed.

During sizeup, you determined which side of the severed log will probably remain the most stationary, providing the anchor point for the underbuck. A common mistake is to place the underbuck on the side that is easiest to reach. If this side of the log moves when the log is severed, the saw could be damaged.

To underbuck, use a mechanical underbuck or plant an ax in the log so the handle can be used as a support for the back of the saw (figure 5-23). Line up the underbuck grooves in the ax handle with the top saw kerf and swing the ax into the log forcefully.

Figure 5-23—An ax planted in the lower part of the

log can work as

an underbuck.

Oil in the underbuck groove will help the saw run easily and will reduce wear on the ax handle. Adjust the handle angle to allow room for the saw to be inserted and for the underbuck to be parallel to the saw kerf.

If you are placing an offset cut, allow for about ½ inch of offset toward the ax head.

If you are underbucking a compound cut, try to have the cuts match exactly because an offset could prevent the log from being freed. Several more wedges may have to be placed in the top cut to provide additional bearing pressure on the kerf faces, holding the log in place.

Lubricate both sides of the saw and the ax handle grooves.

Your body position will determine how to position the ax handle.

Place the back of the inverted saw in the underbuck groove. The saw typically starts out at an angle of about 45 degrees from horizontal. Your guiding hand holds the back of the saw. With a light downward pressure on the underbuck, push the saw forward. Pressure on the underbuck needs to be consistent on the push and pull strokes.

After several strokes, you can remove your hand and continue normal cutting. With continued downward pressure, the end of the saw will be doing more of the cutting and the saw blade will level out. As the cut nears completion, be prepared for the severed log to drop.

Single Bucking with Top Bind: Top Cutting—Several methods can be used to buck a log when there is top bind and not enough room to get the saw under the log for underbucking.

All sawing will be from the top. Do a good job of wedging to keep the kerf open. Follow the instructions for wedging (chapter 3). Periodically, drive all the wedges until they are snug. Do not allow wedges to contact the saw.

The cut will want to open up at the bottom. A log or other material can be placed under the log segment that will drop when the cut has been completed, reducing the distance it will fall.

Single Bucking with Bottom Bind: Top Cutting—When there is bottom bind and too little room to get the saw under the log for an undercut, all the cutting will be done from the top. The main problem with bottom binds is that standard wedging does not help. In addition, when the log is severed, segments of the log may drop or roll.

Cut the log as explained for top cutting with single bucking. Lightly place a small plastic wedge at the top of the cut. Do not drive the wedge in.

This wedge will show when the kerf begins to open. When the kerf opens, drive two fan-shaped metal wedges across the kerf. The point is to slow the opening of the kerf and the settling of the log.

As the kerf opens at the top, it exerts more and more compression on the uncut wood. If the force becomes too great, the uncut wood may slab off, possibly damaging the saw. The saw could be damaged even if the log does not slab.

When the log is sawed through, the log's weight may pull out the metal wedges, causing the log to drop and roll.

The sawyer needs to keep sawing or even speed up sawing to keep opening the kerf and relieving the compression pressure. The combination of using wedges to slow the kerf's opening and speeding up the cutting can prevent additional binding.

The best technique to reduce the effects of a bottom bind is to insert a stick into the opening saw kerf. A straight, finger-sized limb about a foot long can be inserted into the opening kerf at the top of the log (do not use plastic wedges).

As the kerf continues to open, the stick slides into the kerf. The stick does not drop to the back of the saw because it is too thick. As the cut is completed, the two halves of the severed log hinge on the stick. The bottom opens up, allowing the saw to drop free.

Single Bucking with Bottom Bind: Underbucking—If you have bottom bind and can get under the log, make the first cut from the bottom. In this case, wedging is not as critical. When the first cut is from the top, fan-shaped metal wedges can reduce the speed at which the kerf opens. A stick can be inserted into the opening top cut if the log is large enough for the stick to fit into the kerf.

Single Bucking with End Bind—If more than one cut is being made, make the top cut first or make the cut where the log has the least amount of weight above the cut. This reduces the end bind on the second cut.

If you are cutting down directly from the top, use more plastic wedges around the cut, especially as it progresses below the centerline of the log. This reduces the possibility of binding.

Single Bucking with Side Bind—This is one of the most difficult and hazardous situations involving binds.

If there is room below the log for the saw's end to clear, cut the side with compression wood first. The finish cut is on the side with tension wood. Alternately saw and chop out wood with an ax. The saw should be in a nearly vertical position. Always find a safe position to make the finish cut.

If the log is on the ground in a side-bind situation, options are limited. For trees larger than 20 inches d.b.h., the only options are to place a cut beyond the side-bind area or to cut out the area with an ax.

Double-Bucking Techniques

New sawyers should master the skills of single bucking before learning double bucking.

The reasons to double buck are:

- Large logs can be sawed more easily by two sawyers.

- Two sawyers can transport equipment more easily than one.

Usually the uphill sawyer (the primary sawyer who will finish the cut) lubricates the saw and positions a guiding hand on the back of the saw for the first few strokes.

If you are going to roll the severed log out of the way, be sure to make a compound cut. The goal is for the sections of log to have as little surface resistance against each other as possible. The larger the log, the more careful the planning needed for the compound cut. Make the cuts where you will be safe and you will be able to move the log.

Your dominant hand (power hand) should be placed firmly around the saw's handle. Your other hand can rest on top of the handle to guide the saw and to help maintain your balance. Your dominant hand pulls the saw straight back to the side of your body. Sawyers often grip the saw too tightly with their guiding hand. This tends to pull the saw across their body.

ALWAYS pull—NEVER push!

Allow your partner to pull. Pushing may cause the saw to buckle.

As one sawyer pulls, the other sawyer keeps a relaxed grip on the handle. The sawyer neither pushes nor holds back. Holding back is called riding the saw, which makes it harder for the other sawyer to pull.

If you momentarily relax your grip, the saw will reposition itself in your hand for the pull stroke. Relaxing your grip also increases circulation in your hands and reduces fatigue.

If one sawyer needs to change body position (to drop to a kneeling position, for instance), the other sawyer needs to adjust the angle of the saw to accommodate the change.

Wedges should be placed as soon as there is room behind the back of the saw to insert them. For long logs, two wedges usually are inserted at the 10 and 2 o'clock positions and driven firmly until they are snug. If the wedges are not snug, the saw could be damaged.

Be sure the saw travels into and out of the kerf in a straight line. Look down the saw toward the other sawyer.

If the cut is going to be finished by single bucking, whenever EITHER sawyer determines it is time to stop sawing, both sawyers STOP. Do not allow your judgment to be swayed by your partner even if it means more single bucking will need to be done. Leave the downhill side as soon as possible.

If the log is going to be severed by double bucking (on flat terrain) be sure that the circle (the arc) of the saw remains parallel to the ground. Do not have one end higher than the other.

Usually the bottom bark has not been removed. Carefully look at the shavings. When they change to the color of the bark, the log has been severed and only the bark is holding it. If the log fell on mineral soil, the impact may have forced rocks into the bark. The rocks can dull the saw's teeth. Usually the cut is stopped when woodcolored fibers are no longer being removed.

When the cut is finished, or when it is being finished by single bucking, remove the handle on the downhill side of the saw and allow the uphill sawyer to pull the saw free. Make sure the downhill sawyer is in a safe location before the uphill sawyer continues the cut.

DO NOT remove the wedges before removing the saw. The wedges may be holding the log in position. When wedges are removed in these situations, the severed log shifts, binding the saw. If the wedges are loose enough to be lifted straight up, it is safe to do so—do not wiggle them out. Once the saw is free, the wedges can be safely removed while you are standing on the uphill side of the log. Be prepared for the log to move.

Felling Preparation and Techniques

Safety Considerations

Safety considerations for felling apply whether you are using chain saws or crosscut saws. The tree and the forces acting on it cannot tell the difference between handtools and power tools.

Situational Awareness

Analyze the felling job by considering:

- Species (live or dead)

- Size and length

- Soundness or defects

- Twin tops

- Widow makers and hangups

- Frozen wood

- Rusty (discolored) knots

- Punky (swollen and sunken) knots

- Spike top

- Footing

- Heavy snow loading

- Bark soundness

- Direction of lean

- Degree of lean (slight or great)

- Head lean or side lean

- Nests or insect holes

- Splits and frost cracks

- Deformities, such as those caused by mistletoe

- Heavy branches or uneven weight distribution

- Damage by lightning or fire

Check the base of the tree for:

- Thud (hollow) sound when struck

- Conks and mushrooms

- Rot and cankers

- Shelf or bracket fungi

- Wounds or scars

- Split trunk

- Insect activity

- Feeding holes

- Bark soundness

- Resin flow on bark

- Unstable root system or root protrusions

Examine surrounding terrain for:

- Steepness

- Irregularities in the ground

- Draws and ridges

- Rocks

- Stumps

- Loose logs

- Ground debris that can fly or kick up at the sawyer

Examine the immediate work area for:

- People, roads, or vehicles

- Powerlines

- Hangups and widow makers

- Snags

- Fire-weakened trees

- Reserve trees

- Structures

- Openings to fall trees into

- Other trees that may be affected

- Hazards such as trees, rocks, brush, or low-hanging limbs

- Other trees that may have to be felled first

Walk out and thoroughly check the intended lay where the tree is supposed to fall. Look for dead treetops, snags, and widow makers that may cause kickbacks, allow the tree to roll, or cause another tree or limb to become a hazard.

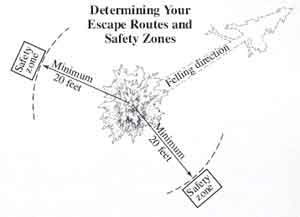

Escape routes must be predetermined paths where the sawyer can escape once the tree is committed to fall or has been bucked. Safety zones should be no less than 20 feet from the stump, preferably behind another tree that is sound and large enough to provide protection. Escape routes and safety zones should be 90 to 135 degrees from the direction of fall. Sawyers must select and prepare the work area and clear escape routes before starting the first cut.

Felling Sizeup

Most accidents are caused by falling debris. Watch overhead throughout the cut, glancing regularly at the saw, the kerf, and the top of the tree.

When you approach the tree to be felled, observe the top. Check for all overhead hazards that may come down during felling.

Look at the limbs. Are they heavy enough on one side to affect the desired felling direction? Do the limbs have heavy accumulations of ice and snow?

When the limbs entangle with the limbs of other trees, they can snap off or prevent the tree from falling after it has been cut.

Windspeeds higher than 15 miles per hour may be strong enough to affect the tree's fall. When there are strong winds, stop felling. Other trees and snags in the area also may blow over. Erratic winds require special safety considerations.

Check all snags in the immediate area for soundness. A snag may fall at any time with a gust of wind, the vibration of a tree fall, or as the snag's roots succumb to rot. If it is safe to do so, begin by felling any snag in the cutting area that is a hazard.

Clear small trees, brush, and debris from the base of the tree. Remove all material that could cause you to trip or lose balance. Also remove material that will interfere with your use of the saw, wedges, and ax. Be careful not to fatigue yourself with unnecessary swamping. Remove only as much material as necessary to allow you to work safely around the base of the tree and to provide escape routes.

The importance of sound holding (hinge) wood cannot be overemphasized. Determine the condition of the holding wood by sounding it with an ax. Look up while doing so, in case any debris is dislodged. Check for frost cracks or other weak areas in the holding wood. The desired felling direction can be adjusted to compensate for weak areas in the holding wood. The depth of the undercut also can be adjusted to take advantage of the holding area.

Most trees have two natural leans: the predominant head lean and the secondary side lean. Both must be considered when determining the desired felling direction. The desired felling direction usually can be chosen within 45 degrees of the combined lean, provided there is enough sound holding (hinge) wood to work with, especially in the corners of the undercut.

Use a plumb bob or ax to evaluate the tree's lean. Project a vertical line up from the center of the tree's butt and determine if the tree's top lies to the right or left of the projected line.

A pistol-grip tree has a curve at the base of the trunk and may appear to be leaning in one direction while most of the weight of the tree is actually leaning in another direction.

Look at the treetop from at least two different spots at right angles to each other. You will do so again during the sizeup, but take every opportunity to determine the correct lean.

In summary, during felling sizeup:

- Observe the top.

- Check for snags.

- Swamp out the base.

- Assess the soundness of the holding wood.

- Assess the lean.

Establishing Escape Routes and Safety Zones

With the desired felling direction in mind, determine your escape routes. Consider the side of the tree where you will make your final cut and select a path that will take you at least 20 feet behind the stump when the tree begins to fall. Don't choose a path directly behind the tree. It is best to prepare two escape routes in case you switch your location on the final cut (figure 5-24).

Figure 5-24—Keep the felling direction in mind when

planning

escape routes.

Look for a large solid tree or rock for protection. Safety zones must be at least 20 feet away from the stump and not directly behind it. Practice the escape routes, making sure that debris that could trip you is cleared.

Walk out the intended lay of the tree (figure 5-25) and look for any obstacles that could cause the tree to kick back over the stump or cause the butt to jump or pivot as the tree hits the ground. Look for any small trees or snags that could be thrown into your escape routes. Ensure that the cutting area is clear of people.

Reexamine the escape routes. Be sure that your chosen routes will be the safest escapes—before you begin to cut.

Figure 5-25—Check the intended lay of the tree for obstacles.

Placing the Undercut

After the escape routes are established, specific methods shall be used to cut the tree. We are going to discuss just the conventional undercut because of its broad application for all timber types and because it provides a solid foundation from which to learn additional cutting techniques.

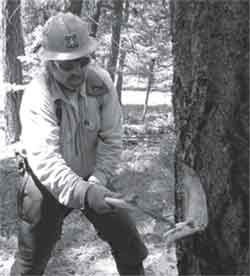

Before beginning the undercut, prepare the tree for cutting (figure 5-26). Bark should be removed to:

- Keep the saw sharp.

- Make wedges more effective.

- See how the cuts are lining up.

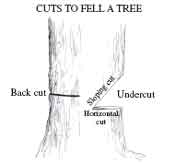

It takes three cuts to fell a tree. Two cuts form the undercut (or face cut) and the third forms the back cut. The correct relationship of these cuts results in safe and effective tree felling. Before discussing the felling procedure, we will analyze the mechanics of the felling cuts. Undercutting and back cutting construct the hinge that controls the fall of the tree and the direction of fall.

The undercut serves two purposes. First, it allows the tree to fall in a given direction by removing the tree's support in the direction of the face. Second, it enables control because the tree slips off—rather than jumps off—the stump.

Figure 5-26—An ax can be used to remove the bark.

Ways to make the undercut:

- Make the undercut with a crosscut saw, or

- Make the horizontal cut with a crosscut saw and chop

the undercut out with an ax, or

- Chop out the entire undercut with an ax.

Chopping Out the Undercut With an Ax—Although this approach may appear to be the hardest, it has advantages in certain situations. If this method is used, the cut should be level so the back cut, which is parallel to the undercut, will be level also.

Advantages of chopping out the undercut:

- Chopping out the undercut is about as fast as sawing

the undercut for smaller trees.

- Chopping out the undercut may be best in restricted

areas where one side of the tree does not offer standing

room for the sawyer or does not have adequate clearance

for the end of the saw.

- Chopping out the undercut will allow the sawyer to

limit the number of cuts. It is hard to apply saw oil to the bottom edge of a saw in the horizontal felling position.

Chopping out the undercut is especially useful

if the tree is extremely pitchy.

- Chopping out the undercut is a good alternative when the saw handles cannot be vertical, or when a stiff bucking saw is used, or for any combination of factors that lead to an uncomfortable sawing position.

Using a Crosscut Saw and an Ax—Make the horizontal cut with a saw and chop out the undercut with an ax. The horizontal saw cut is put in first, allowing the sawyer to place a level cut more easily. The ax helps keep the cut free of any dutchmans.

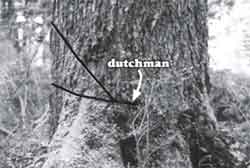

Making the Undercut With a Crosscut Saw—When making the undercut, take care not to bypass the cuts. When the cuts don't meet exactly, they create a dutchman (figure 5-27).

Figure 5-27—When the sloping cut and the horizontal

cut do not

meet exactly, a dutchman is formed. This kerf-wide

cut makes the

direction of the tree's fall harder to predict. It can also

cause the

tree to barber chair, lifting the log off the stump and placing

the

sawyers at great risk.

ALWAYS pull—NEVER push!

Allow your partner to pull. Pushing may cause the saw to buckle.

Observe overhead hazards and look up often during the undercut (figure 5-28).

Figure 5-28—Hazard trees need to be removed

to prevent anyone

from working under them.

Ideally, the undercut is made in the same direction as the tree's lean. Depending on structures, roads, other trees, and trails, the desired felling direction may be to one side or the other of the lean. Normally, the desired direction should be less than 45 degrees from the lean.

If there is any danger from above, such as snags, the sawyer should cut while standing to make it easier to watch the top and escape more quickly. The horizontal cut is a level cut. The horizontal cut dictates the direction of fall if the relationships of the three cuts are maintained. After selecting the desired felling direction, estimate one-third the tree's diameter and begin the horizontal cut.

The specific direction of the undercut is determined by gunning the saw (figure 5-29). Place the back of the saw against the back of the undercut. The saw's teeth should point in the direction the tree should fall.

Figure 5-29—Gunning the saw helps determine the

specific direction

of the undercut. (Photo has been

digitally altered to remove distracting

items.)

Trees with leans may not allow you to insert the horizontal cut as deep as one-third of the tree's diameter without pinching the saw.

The sloping cut needs to be angled so that when the undercut closes the tree is fully committed to your planned direction of fall. As the cut closes, the holding wood breaks.

A general rule for the sloping cut is that is should be at a 45-degree angle. Remember that it is important that the undercut not close until the tree is fully committed to your planned direction of fall (figure 5-30). Line up the sloping cut with the horizontal cut so that they meet, but do not cross. When the cuts cross, a dutchman is formed. If the tree were felled with a dutchman, first the dutchman would close, then the tree would split vertically (barber chair), or the holding wood would break off. Felling control would be lost. Practicing on high stumps will help you become skilled at lining up these cuts.

Figure 5-30—An undercut and a back cut are required

to fell a tree.

A horizontal cut and a sloping cut make up

the undercut. Often, the

sloping cut is made with an ax

instead of a crosscut saw. The back

cut is the third

cut needed to fell a tree.

The holding wood is the wood immediately behind the undercut. The most important portion of the holding wood is in the very corners of the cut (the first 4 to 8 inches inside the tree). The horizontal and sloping cut must not overlap in this region. If they do, the undercut must be cleaned up so no dutchman is left in these corners. Care must be taken not to cut the undercut too deeply while cleaning up. This will affect the amount of room available for wedges.

Once the undercut has been cleaned, place the saw back in the face and recheck the gunning direction. The saw handle will point in the felling direction. If the tree is not gunned in the direction that you want it to fall, extend the horizontal and sloping cuts as needed.

Cutting the Back Cut

The third cut needed to fall a tree is the back cut. The relationship of this cut to the undercut is important for proper tree positioning and the sawyers' safety.

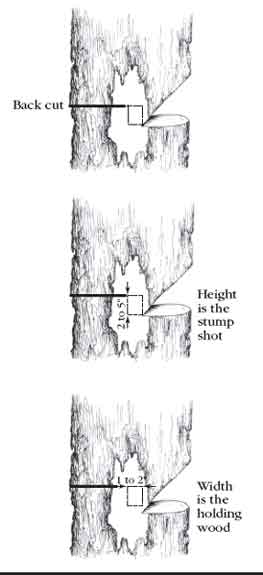

The best way to envision these cuts is by the use of a rectangle (figure 5-31). The bottom corner is the back of the horizontal cut. The opposite upper corner will be the back of the back cut.

Figure 5-31—An imaginary rectangle can help the sawyer

understand

the importance of the back cut. The dimensions of

this rectangle

are based on a 24-inch-diameter tree.

The height of the rectangle is referred to as the stump shot. It is an antikickback device to prevent the tree from kicking back over the stump if it hits another tree as it falls. Preventing kickback is especially important to sawyers who are felling trees through standing timber.

The width of the rectangle is the holding wood. As the back cut is made, sawyers must be sure not to cut this wood. Maintaining the holding wood is the key to safe and effective felling.

Hold the saw level so that the back cut will be level when the cut is complete. You want to be sure that when the cut is finished, it will line up with the top corner of the opposite rectangle. If the cut is angled, wedging effectiveness and the height of the stump shot could be altered.

Remove thick bark immediately above and below the back cut's kerf where wedges will be placed. The bark could compress, reducing the lifting power of the wedges.

Keep at least four wedges and an ax readily accessible while making the back cut. The size of the wedges depends on the tree's diameter.

If the tree begins to move and the saw is stuck, do not hesitate—

LEAVE THE SAW!

If two sawyers are working together, before cutting, identify who will take the saw to the escape route.

When the sawyer with the saw is watching from a safe location, the other sawyer can drive the wedges, causing the tree to lift and commit to fall. When the tree begins to move, the sawyer can escape along the escape route from the stump.

While in a safe location, both sawyers need to continue looking up for overhead hazards. There is a tendency to look at the tree as it hits the ground, leaving the sawyers unaware of limbs that may be thrown back from other trees near the stump. LOOK UP. If rocks or other material are dislodged when the tree hits the ground, yell a warning.

For crosscut saw felling operations, if two sawyers are needed or if an observer/spotter is needed, justification for additional personnel, and the implementation process, shall be documented in the JHA, as required by the Health and Safety Code Handbook.