Chapter 3—Chain Saw Use and Maintenance (Suggested time: 2 hours)

Chapter 3—Chain Saw Use and Maintenance (Suggested time: 2 hours)

Chapter objectives:

- Students will learn how to remove the bar and the

chain, inspect them for damage and wear, and clean

them.

- Students will learn how to remove and clean (or replace

the air and fuel filters.

- Students will learn how to inspect the power head

for loose bolts and damage.

- Students will learn how to replace the bar and the

chain.

- Students will learn how to file the chain.

Chain Saw Operation

The bar and chain are the most important parts of your chain saw. A sharp chain produces shavings that fall to the ground away from the power head. A clean bar in good condition guides the chain through the cut, making a straight, true cut.

A dull chain produces sawdust that gets sucked into the air filter, reducing power by limiting the airflow to the power head. A dull chain does not allow the saw to cut smoothly and puts unnecessary strain on the power head. The sawyer is forced to saw into the cut, increasing the stress on the power head. An improperly maintained bar and chain will damage the chain saw.

As the sawyer works harder to make the saw cut, the sawyer may become fatigued, increasing the risk of accident or injury. A dull chain also increases the risk of kickback.

The primary purpose of the chain saw and crosscut saw training and certification program is to provide for the safety of all employees who operate saws. Selecting the proper chain is important to the safe operation of a chain saw.

Chain Saw Components

Saw chain—The three most common types of cutter teeth used by the Forest Service are chipper, chisel, and semichisel. Saw chain is made up of several parts that work together and must be maintained properly for maximum performance and safety.

The cutter is the part of the saw chain that does the cutting. The saw chain has left- and right-hand cutters so that the saw chain will cut evenly through the wood.

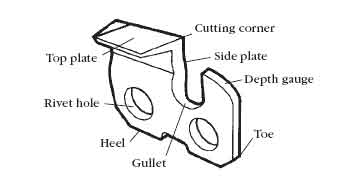

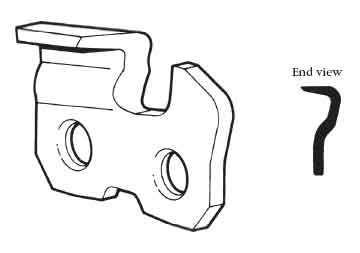

The depth gauge (referred to as a raker in some parts of the country) determines the depth of the cut (figure 3-1).

Figure 3–1—The depth gauge is the part of the tooth

used to set the

thickness of the shaving.

—Oregon Maintenance and

Safety Manual, permission

by Blount, Inc.

The three basic types of cutters include:

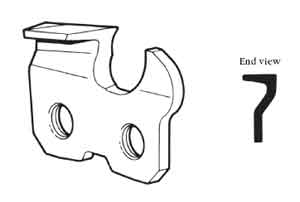

Chipper: The most versatile cutter type. Chipper chain (figure 3–2) is the easiest to file and will tolerate the most dirt and dust. Chipper chain cuts smoothly and is well suited for many Forest Service chain saw operations.

Figure 3-2—The chipper is the most versatile cutter type.

Chipper

chain is easy to file, will tolerate the most dirt, and can

be used for

many types of sawing operations.

—Oregon

Maintenance and Safety Manual, permission by Blount, Inc.

Chisel (figure 3–3): The most aggressive cutter type. It is designed for production timber felling and should be used only by experienced sawyers. Square-ground chisel chain requires a file that fits the square shape of the cutting edge. It is more difficult to file than other types of chain. No file guide is available. Round-ground chisel chain may be filed with a round file and file guide. All chisel chain dulls very quickly when it is exposed to dirt or dust. It is not recommended for brushing or limbing because of the potential for kickback.

Figure 3–3—The chisel is the most aggressive cutter type.

Chisel chain

should be used only by experienced sawyers.

—Oregon Maintenance and

Safety Manual, permission by Blount, Inc.

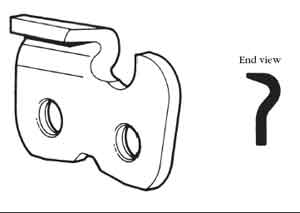

Semichisel (figure 3–4): A less aggressive cutter type than chisel. A round file is used with a file guide when filing semichisel chain. The semichisel cutter is more tolerant of dirt and dust and stays sharp longer than the other cutters.

Low-kickback chain is the most desirable chain for training inexperienced sawyers. The chain cuts smoothly and is ideal for cutting brush, small-diameter material, dimensional lumber, house logs, and other materials that normally aren't cut with chain saws. Low kickback chain is available with chipper, chisel, and semichisel cutters.

Figure 3–4—The semichisel cutter is less aggressive than

the chisel

cutter, will tolerate some dirt, and stays sharp longer than

the chisel

and the chipper cutters.

—Oregon Maintenance and Safety Manual, permission by

Blount, Inc.

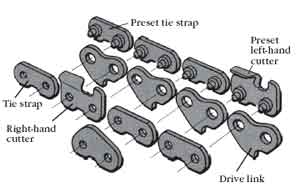

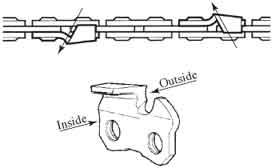

Parts of the chain (figure 3-5).

Figure 3-5—Parts of the chain.

—Oregon Maintenance and

Safety Manual, permission by Blount, Inc.

Tie strap: Holds the parts of the saw chain together.

Drive link: Fits in the bar groove so the bar can guide the chain and into the chain sprocket so the power head can drive the chain around the bar.

Cutter sequences (figure 3-6).

Figure 3–6—The cutter sequences for three types of chains: standard,

semiskip, and skip (full skip).

—Oregon Maintenance and Safety Manual, permission by Blount, Inc.

Standard: This chain has a cutter sequence of: left-hand cutter, tie strap, right-hand cutter, tie strap, left-hand cutter, tie strap, right-hand cutter—for the length of the chain.

Semiskip: This chain has a cutter sequence of: left-hand cutter, two tie straps, right-hand cutter, one tie strap, left-hand cutter, two tie straps, right-hand cutter, one tie strap, left-hand cutter—for the length of the chain.

Skip or full skip: This chain has a cutter sequence of: left-hand cutter, two tie straps, right-hand cutter, two tie straps—for the length of the chain.

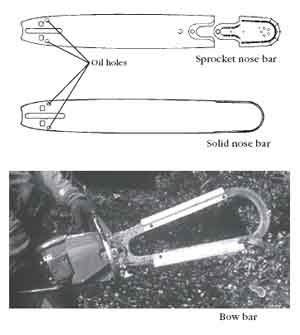

Guide bar—The guide bar supports and guides the saw chain.

The most common types of bars are solid nose and sprocket nose (figure 3-7). A sprocket nose bar has a sprocket in the nose to reduce drag and help the chain move freely around the bar. Generally, a solid nose bar is found on small saws. The bar is solid without a sprocket.

Figure 3-7—The three most common types of guide bars.

—Oregon

Maintenance and Safety Manual, permission by Blount, Inc.

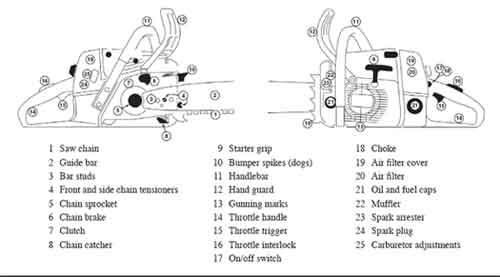

Parts of a chain saw—

—From Chain Safety Manual, permission by Stihl, Inc.

- Bar studs—Hold the bar and chain sprocket cover in

place.

- Front and side chain tensioner—Moves the guide

bar to maintain proper tension on the saw chain.

- Chain sprocket—The toothed wheel that drives the

saw chain.

- Chain brake—Stops the saw chain if it is activated

by the sawyer's hand or by inertia (during kickback).

- Clutch—Couples the engine to the chain sprocket

when the engine is accelerated above idle speed.

- Chain catcher—Helps reduce the risk of the saw

chain contacting the sawyer if the chain breaks or if

the chain is thrown off the bar.

- Starter grip—A rubber or plastic handle attached to

the starter pull rope.

- Bumper spikes (dogs)—Hold the saw steady against

wood.

- Handlebar—Used to hold the front of the saw.

- Hand guard—Activates the chain brake and prevents

the sawyer's hand from contacting the chain.

- Gunning marks—Used to determine the planned

direction of the tree's fall based on the undercut.

- Throttle handle—Used to hold the rear of the saw.

- Throttle trigger—Controls the speed of the engine.

- Throttle interlock—Prevents the throttle from being

activated unless it is depressed.

- On/off switch—Turns the saw on and off.

- Choke—Used for starting a cold saw.

- Air filter cover—Holds the air filter in place and covers

the carburetor.

- Air filter—Prevents dirt, dust, and sawdust from entering

the carburetor.

- Fuel filter—Prevents dirt and other contaminants from

entering the saw's carburetor (not shown).

- Oil and fuel caps—Seal the oil and fuel tanks.

- Muffler—Reduces exhaust noise.

- Spark arrester—Prevents hot sparks from leaving the

muffler.

- Spark plug—Ignites fuel in the power head.

- Carburetor adjustments—Chain saws have

a twostage carburetor that provides fuel to the engine in

any position that a saw may be held. The carburetor

has three adjustments:

- Idle speed sets the speed at which the saw's engine will run by itself.

- Low-end speed controls the mixture of air and fuel on the first half of the throttle.

- High-end speed controls the mixture

of air and fuel on the second half of the throttle.

The high- and low-end adjustments should be made by a qualified saw mechanic. Improper adjustment can result in poor operation or severely damage the chain saw.

The idle adjustment may need to be adjusted in the field. Before adjusting the idle, be sure that the air filter and fuel filter are clean and that you are using the right fuel mixture. Dirty filters or improper fuel mixtures affect the idle speed.

Newer saws designed to meet the U.S. Environmental Protection Agency (EPA) air quality standards may not have all three adjustments.

- Mounts or antivibration system —Buffers between the engine and the handles that reduce vibrations to the sawyer's hands (not shown).

Guide Bar Maintenance

Most guide bar problems develop in the bar rails and are caused by:

- Incorrect chain tension

- Lack of lubrication

- Improper cutting techniques

- Normal wear

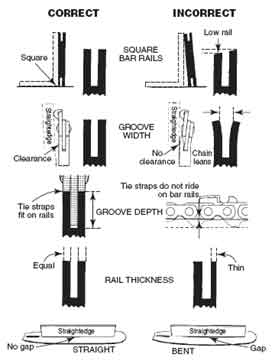

Look for several rail conditions (figure 3–8) when performing daily maintenance on your saw. These conditions can be corrected if they are caught early. If they are ignored, they will destroy the bar or lead to cutting problems. For instance, it may not be possible to cut straight with the saw or to match cuts on larger material. In addition, the chain may be thrown because the chain tension is harder to control.

Figure 3-8—Correcting these rail conditions will

prevent damage

to the bar and cutting problems.

—Oregon Maintenance and Safety Manual,

permission by Blount, Inc.

- Rails are worn down and the groove becomes shallow.

If the groove is too shallow and the tie straps do

not touch the rails, replace the bar.

- The outside edges of the rails develop wire edges. Use

a flat file to remove them.

- The rail is worn low on one side. This causes the chain

to cut at an angle. The bar will have to be ground on

a specialized bar grinder. You may need to take the

bar to a dealer or to a trained saw mechanic if your

unit doesn't have a specialized bar grinder.

- The rails show blue discoloration along the bar or at

the tip of the sprocket nose. This discoloration is

caused by lack of lubrication, by poor cutting methods

that push the drive links to the side, by a chain that is

too tight, or by a dull or improperly filed chain. Blue spots are caused by excess heat. The spots are soft and

will wear rapidly: you will need to replace the bar.

- The bar shows excessive wear only behind the nose

on solid nose bars or behind the sprocket on sprocket

nose bars. This wear can be caused by heavy use

near the nose of the bar (such as limbing) or by a

chain that is too loose. You can reduce this wear by

periodically turning the bar over. If wear becomes

extensive, you may need to replace the bar.

- The bar is bent. This can be caused by improper cutting techniques, getting the saw pinched or bound in the cut, or improper transportation (such as carrying a saw loose in the bed of a pickup). Some bars can be straightened at a shop that has the proper equipment.

The condition of the guide bar has as much to do with the performance of your chain saw as the condition of the chain. The bar and the chain work together. When both are in proper condition, the chain saw does the work. All you have to do is guide it.

Chain Tension

Remember three basic rules for tensioning a saw chain:

- Turn the saw off!

- Wear protective gloves.

- Wait until the bar and chain have cooled before adjusting the tension.

Heat causes the bar and chain to expand when the chain saw is being used. If the tension is set while the chain is hot, the chain will be too tight when it cools. Tension that is set too tight can damage the bar and chain. To adjust the chain tension on a solid nose bar:

- Loosen the bar nuts on the side of the saw.

- Pull the nose of the bar up and keep the nose up as

you adjust the tension.

- Turn your saw's adjustment screw until the bottoms of

the lowest tie straps and cutters just touch the bottom

of the bar.

- Still holding the nose up, tighten the rear bar nut,

then the front bar nut.

- While wearing gloves, pull the chain along the top of the bar several times from the engine to the tip. The chain should feel snug, but pull freely.

The tension must be tighter on a sprocket nose bar than on a solid nose bar. To adjust the tension on a sprocket nose bar:

- Loosen the bar nuts on the side of the saw.

- Pull the nose of the bar up and keep the nose up as

you adjust the tension.

- Turn your saw's adjustment screw until the bottoms

of the lowest tie straps and cutters solidly contact the

bottom of the bar.

- While wearing gloves, pull the chain along the top of the bar several times from the engine to the tip. The chain should feel snug, but still pull freely.

Daily Saw Maintenance

As the chain goes around the bar, it wears the bar and the chain. Because the bar is made of softer metal, the bar wears more than the chain. Generally, one rail will wear more than the other, causing the saw to cut at an angle if the bar and the chain are not maintained properly.

Chain saws have a chain oiler to minimize wear and prolong the life of the bar and chain. The oiler provides oil through a small hole in the bar that lines up with the oiler on the power head.

As oil is pumped through the oil hole, the chain carries it around the bar, lubricating the top, bottom, and roller tip. During operation, debris begins to build up in the chain groove. If the groove is not cleaned, oil cannot lubricate the entire bar, causing excessive wear and damage. If the oiler is properly adjusted, a full tank of gas will run dry before the oil tank is empty. As a general rule, a tank of oil should last as long as or longer than a tank of gas.

Clean and rotate the bar each time you file the chain or at least once a day. Be sure to clean the bar after filing the chain because the filings act as an abrasive, increasing the wear on the bar.

Cleaning Exercise—

Remove the bar and chain for inspection and cleaning.

- Check the bar for wear. Look for uneven rails, flared

edges, cracks, and other damage that would require

the bar to be repaired or serviced.

- Clean the chain groove and oil holes. The proper

method for cleaning the chain groove is to start at the

tip with the bar tool and clean toward the base, moving

debris away from the roller tip. Be sure that the oil

holes are clean.

- The sprocket nose (roller tip) should spin freely.

- Grease the roller tip.

Remove and clean the air filter. Never use an air hose to blow out the air filter.

- Take care not to damage the filter. Gently tap the filter

against another surface. Don't rub or scrape it. Do not

clean the filter with saw fuel. A damaged air filter can

allow dust and debris into the engine, causing excessive

wear and other problems.

- Follow the manufacturer's recommendations (found in the instruction manual) for cleaning the air filter and determining whether it needs to be replaced. A dirty or plugged air filter reduces the power and performance and may cause other seemingly unrelated problems.

Check the muffler and spark arrester. Replace the screen if it has any holes.

Remove the spark plug.

- Check for fouling.

- The tip of the plug should be beige, not black.

- The plug should be dry.

- Check the plug weekly when the saw is in frequent use.

Inspect the power head for loose bolts and damage.

- Tighten the bolts or repair the power head, if needed.

- Check the handlebars for loose bolts or cracks.

- Check the bumper spikes (dogs) for loose or bent bolts.

- Check the mounts. They are the antivibration system. Look for cracks in the rubber. Excessive movement of the engine or a loose feeling when the saw is held by the handles and shaken indicate that the mounts may be broken or that they need tightening.

Replace the bar and chain.

- Rotate the bar so it wears evenly.

- Check for proper alignment of the bar with the bar

studs, adjuster, and oiler.

- Check the chain tension. The chain should be adjusted

so that it doesn't hang from the bar but still turns freely.

- Check the chain brake to make sure it's operating properly.

Chain Maintenance

Chain maintenance is crucial to the performance of any chain saw. Before beginning any work assignment, follow four basic rules to maintain the saw chain for top performance and safe operation.

- Your chain must be sharp. When it is, the chain does

the work. When the chain is dull, you do the work,

making you fatigued and increasing the wear on the

bar and chain.

- Your depth gauges must be set correctly. The gauges'

depths and shapes are critical to the saw's performance

and your safety.

- Your chain must be correctly tensioned. More bar and

chain problems are caused by incorrect chain tension

than by any other single problem.

- Your chain must be well lubricated. Your bar, chain, and roller tip need a steady supply of oil. Otherwise, your bar and chain will be subject to excessive wear and damage.

Several conditions can increase the chain's potential for kickback, the risk that the chain might be thrown or broken, or the risk of other hazards. Look for these conditions when inspecting your chain saw:

- Loose chain tension

- Incorrect chain angles (generally caused by improper filing)

- Dull chain

- Alteration of chain features designed to reduce kickback

- Incorrect depth gauge settings (generally too deep)

- Improper shape of depth gauges (rakers)after filing

- Incorrectly installed chain parts

- Loose rivets, or cracks and breaks in any part of the chain

Chain Filing

This section focuses on chain filing with a round file and a clamp-on (hand-held) file guide that clamps on the file, sometimes called a file holder. Using these files is the least complicated, least expensive, and most efficient way to file saw chain by hand in the field. Select a file that is the proper diameter for the saw chain.

After the saw chain has been hand filed a few times, it should be ground on a chain grinder to restore angles that may have changed during hand filing and to grind all cutters to the same length.

Understanding how a cutter works will help you see why proper chain maintenance is so important.

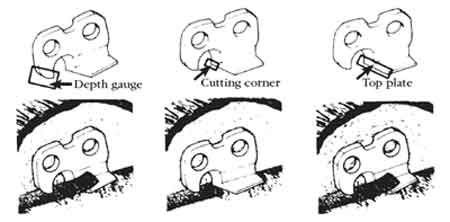

The depth gauge rides on the wood and controls the depth at which the cutting corner bites into the wood (figure 3-9).

Figure 3-9—The depth gauge controls the depth at which a tooth's

cutting corner bites into the wood.

— Oregon Maintenance and Safety Manual, permission by Blount, Inc.

The cutting corner and side plate sever the wood fibers across the cross grain.

The top-plate cutting angle chisels out the severed wood fibers, lifting them from the kerf.

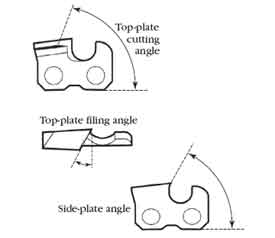

Three angles must be maintained when filing or grinding a saw chain (figure 3-10). A clamp-on file guide maintains these angles. The angles may vary on different types of saw chains.

Figure 3-10—Maintain the top-plate cutting angle, top-plate filing

angle, and side-plate angle.

—Oregon Maintenance and Safety Manual, permission

by Blount, Inc.

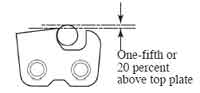

Sharpening Cutters With a Round File—Be sure that the chain is tensioned properly. The file must be held at least one-fifth of the file's diameter above the cutter's top plate (figure 3-11). The clamp-on file guide positions the file for you.

Figure 3-11—Hold the file at least one-fifth of the file's diameter

above the cutter's top plate.

—Oregon Maintenance and

Safety Manual, permission

by Blount, Inc.

Maintain the correct top plate angle (as marked on the file guide) by keeping the filing angle parallel with the chain (figure 3-12).

Figure 3-12—The correct top-plate angle is marked on the file

guide.

—Oregon Maintenance and Safety Manual, permission by Blount, Inc.

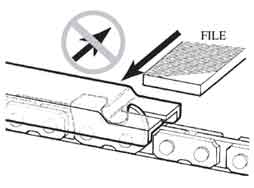

Sharpen cutters on one side of the chain first, filing from the inside of each cutter to the outside. Turn the saw around and repeat the process for the remaining side (figure 3-13).

Figure 3-13—Sharpen the cutters on one side of the

chain before

turning the saw around to sharpen the other side.

—Oregon Maintenance

and Safety Manual, permission by Blount, Inc.

If the chrome surface of the top or side plates has been chipped, file until the chip has been removed from the chrome surface.

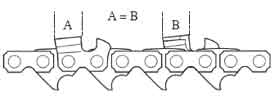

Keep the length of all cutters equal (figure 3-14).

Figure 3-14—All cutters should be the same length.

—Oregon Maintenance

and Safety Manual, permission by Blount, Inc.

How To Set Depth Gauges—Use a depth-gauge tool with the correct built-in setting for the chain. Place the tool on top of the chain so one depth gauge protrudes through the slot in the tool (figure 3-15).

If the depth gauge extends above the slot, use a flat file to file the depth gauge level with the top of the tool. Never file a depth gauge lower than the top of the tool.

Figure 3–15—A depth gauge protrudes through the slot

in the depthgauge

tool.

—Oregon Maintenance and Safety Manual, permission by Blount, Inc.

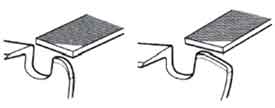

After lowering a depth gauge, round off its leading edge (figure 3-16).

Figure 3–16—After lowering a depth gauge,

always round off its

leading edge.

—Oregon Maintenance and

Safety Manual, permission by Blount, Inc.

Chain Filing Exercise—

- Wear appropriate gloves for hand protection as described

in your JHA.

- Make sure the chain is tensioned properly.

- Maintain the correct top-plate angle (as marked on the

file guide) by keeping the filing angle parallel with the

chain.

- File one side of the chain, then the other.

- Keep the length of all cutters equal.

- Set depth gauges with a depth-gauge tool.

Saw Transportation

Saws must be transported in a way that protects them from being damaged, from injuring people, and from damaging property and equipment.

Transporting Chain Saws in a Vehicle—

- Keep the bar and chain covered with a chain guard.

- Properly secure the chain saw to prevent it from being

damaged and to prevent fuel from spilling.

- Never transport a chain saw or fuel in a vehicle's passenger compartment.

Transporting Chain Saws by Hand—The muffler and power head can reach extremely high temperatures. Avoid these areas when carrying a saw that has been used recently.

- When carrying the saw for short distances, set the

saw at idle speed and set the chain brake.

- When carrying the saw farther than from tree to tree,

or in hazardous conditions (such as slippery surfaces

or heavy underbrush), and in all cases if the saw is

carried more than 50 feet, the saw shall be shut off

and carried in a way that prevents the chain, muffler,

and bumper spikes (dogs) from contacting your body.

- When carrying the saw on your shoulder, take extra care because of the sharpness of the chain and bumper spikes (dogs). A long-sleeved shirt, gloves, and a shoulder pad must be worn. The bar, chain, and bumper spikes (dogs) should be covered, preferably with a manufactured bar and chain cover. Chain saw chaps can be used to cover the bumper spikes (dogs).

Safe Chain Saw Use

The methods to safely start and operate a saw can vary with the make and model.

Starting Procedures—

Take extra care when starting your chain saw. Because you won't have both hands on the saw, you will need to be more careful to maintain complete control. Remember that on/off switches may vary with different makes of saws.

- Ensure that appropriate PPE is available and is worn

correctly.

- Maintain a secure grip on the saw at all times.

- Always start the saw with the chain brake engaged.

- Start the saw on the ground or where it is supported

firmly with the nose of the saw bar over a stump or

log. To successfully start a cold saw, "feather" the throttle

trigger. Avoid engaging the throttle lock or the

fast idle position of the on/off switch.

- Make sure that the saw's bar and chain do not contact

anything.

- "Drop starting" a chain saw is strictly forbidden. Do not drop start a chain saw. This is the most dangerous method of starting a saw because you have no control of the saw.

Starting the Chain Saw on the Ground—

- Set the chain brake.

- Place the saw on firm ground in an open area (figure

3-17).

- Grip the front handlebar firmly with your less dominant

hand.

- Pull the starting rope with your dominant hand until

you feel resistance.

- Give a strong, brisk pull. Gradually return the starting rope to the saw housing. Do NOT allow the starting rope to snap back.

Figure 3-17—Start the saw on firm ground.

Operational Safety

A full-wrap handlebar allows cutting from both sides of the tree using the bottom of the bar, the part of the bar that can be used aggressively. In some situations the ability to cut wood rapidly is critically important for safety. Full-wrap handlebars are designed to be used by both the left and the right hand. The sawyer's thumb should always be wrapped completely around the handlebar, no matter how the saw is turned. The thumb and fingers are essential for maintaining control of the chain saw, especially during a kickback. The grip on the chain saw should be firm, but not overly tight.

Handling—

- Never operate a chain saw with one hand. You do not

have control of the saw and increase the risk that you

will be injured if the saw kicks back.

- Always grip the saw firmly with both hands.

- Grasp the throttle handle firmly with your dominant

hand and grasp the handlebar with your less dominant

hand. Your fingers must encircle the handlebar with

the thumb wrapped underneath.

- Never operate a chain saw with the throttle lock

engaged. If you do, you will not be able to control the

saw or the chain speed.

- Make sure your work area is clear of people and obstacles,

such as rocks, stumps, holes, or roots that may

cause you to stumble or fall.

- Make sure that the saw chain does not contact any

materials such as rocks or wire. Such contact is a

safety hazard and will dull the chain. The chain will

require filing or it may be damaged in ways that filing

cannot correct.

- Cutting with the bottom of the bar pulls the chain saw away from the sawyer. Cutting with the top of the bar pushes the saw back at the sawyer. Cutting with the bottom of the bar increases efficiency and decreases the sawyer's fatigue.

Reactive Forces—

The laws of physics explain that for every action there is an equal and opposite reaction. These reactions happen very quickly during chain saw operation and can be dangerous.

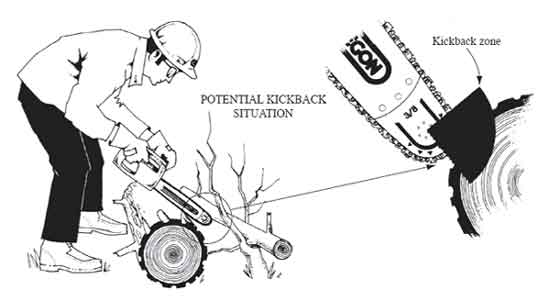

Kickback—Kickback is the most powerful reactive force you will encounter while operating a chain saw. Kickback can occur while felling, limbing, bucking, or brushing when the upper quadrant of the bar nose contacts a solid object or is pinched (figure 3-18).

During kickback, the bar is forced up and back in an uncontrolled arc toward the sawyer. Many factors determine the severity of the kickback and the arc, including: chain speed, angle of contact, condition of the chain, and the speed at which the bar contacts the object.

Figure 3-18—Kickback occurs when the upper quadrant of the bar nose

contacts a solid object or is pinched.

—Oregon Maintenance and Safety

Manual, permission by Blount, Inc.

Ways to avoid kickback:

- Hold the saw with both hands, securely gripping the

handle and the handlebar between your thumb and

forefinger.

- Be aware of the location of the bar's nose at all times.

- Never let the bar's nose contact another object.

- Never cut with the power head higher than your

shoulder.

- Never overreach.

- Pull the saw smoothly out of the cuts. This technique

will help to reduce kickbacks and fatigue.

- Cut one log at a time.

- Stand to the side of the kickback arc.

- Use caution when entering a partially completed cut.

- Use a properly sharpened and tensioned chain at all

times.

- Watch the cut and the log for any movement that may

pinch the chain.

- Use a low kickback chain.

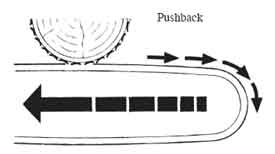

Pushback—Pushback (figure 3-19) occurs when the chain on the top of the bar is suddenly stopped by contacting another object or by being pinched. The chain drives the saw straight back toward the sawyer.

Figure 3-19—Pushback occurs when the chain on the top of the bar

is suddenly stopped by contacting another object or by being

pinched.

—From Chain Safety Manual, permission by Stihl, Inc.

Ways to avoid pushback:

- Only cut with the top of the bar when necessary.

- Watch the cut and the log for any movement that may pinch the top of the bar.

- Do not twist the bar when removing it from a boring cut or underbuck.

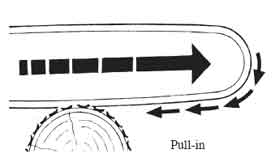

Pull-In—Pull-in occurs when the chain on the bottom of the bar is caught or pinched, and suddenly stops. The chain pulls the saw forward (figure 3-20).

Figure 3-20—Pull-in occurs when the chain on the bottom of the

bar is suddenly stopped by contacting another object or by being

pinched.

—From Chain Safety

Manual, permission by Stihl, Inc.

Ways to avoid pull-in:

- Always start a cut with the chain at or near full speed

and with the bumper spikes (dogs) contacting the

wood.

- Watch the cut and the log for any movement that may pinch the bar. Use wedges to keep the cut open.

Additional Tools

This section includes information about axes, wedges, approved safety containers for fuel and oil, peaveys, and cant hooks.

Axes—Axes are used to remove bark from trees and to drive wedges during felling and bucking. The ax handle should be smooth and free of cracks. The head should be securely attached to the handle. Axes used for driving wedges should have a straight handle.

Single-bit axes need to be heavy enough (3 to 5 pounds) to drive plastic wedges into the trees being felled. The back of the ax (poll) should be smooth, have rounded edges, and be free of burrs to minimize damage to wedges. Pulaskis should never be used to drive wedges.

Always remove branches, underbrush, overhead obstructions, or debris that might interfere with limbing and chopping. Do not allow anyone to stand in the immediate area. Make sure workers know how far materials may fly. Protect all workers against flying chips and other chopping hazards by requiring them to wear the appropriate PPE.

Always position your body securely while working with a tool. Never chop crosshanded; always use a natural striking action. Be alert when working on hillsides or uneven ground. If you cut a sapling that is held down by a fallen log, the sapling may spring back. Be alert for sudden breakage. If you do not need to cut something, leave it alone.

Never use chopping tools as wedges or mauls. Do not allow two persons to chop or drive wedges together on the same tree. When chopping limbs from a felled tree, stand on the opposite side of the log from the limb being chopped and swing toward the top of the tree or branch. Do not allow the tool handle to drop below a plane that is parallel with the ground unless you are chopping on the side of a tree opposite your body.

If the cutting edge picks up a wood chip, stop. Remove the chip before continuing. To prevent blows from glancing, keep the striking angle of the tool head perpendicular to the tree trunk.

Wedges—Wedges are essential tools for safe felling and bucking. They provide a way to lift the tree, preventing the tree from sitting back when it is being felled. A wedge must be inserted into the back cut as soon as possible. Wedges also reduce binds on the saw when bucking logs.

Select the correct wedge for the job. The proper type, size, and length or a wedge varies, depending on its use. The size of the tree being felled or the material being bucked determines the size of the wedge that will be needed. If the wedge is too small, it may be ineffective. If the wedge is too long, it may not be able to do its job without being driven so far into the tree that it contacts the chain.

Always drive wedges by striking them squarely on the head. Drive them carefully to prevent them from flying out of the cut.

Check wedges daily or before each job. Do not use cracked or flawed wedges. Wedges that are damaged need to be cleaned up before they are used again.

Grind wedges to the manufacturer's original shape and angle. Wear eye protection and a dust mask.

Repair any driving tool or remove it from service when its head begins to chip or mushroom.

Carry wedges in an appropriate belt or other container, not in the pockets of clothing.

Most wedges are made out of plastic or soft metal, such as magnesium, and come in different sizes. Use plastic wedges in both felling and bucking operations to prevent the saw chain from being damaged if it contacts the wedges.

The two basic types of wedges used in sawing are single and double taper.

Single-taper wedges (figure 3–21) are simple inclined planes designed to provide lift during tree felling. As the wedge is driven into the back cut, the tree hinges on the holding wood, redistributing the tree's weight. The sawyer must coordinate striking the wedge with the forward sway of the tree, allowing the wedge to be driven more easily and sending less of a shock wave up the tree. Striking the wedge when the tree is in its backward sway sends a severe shock wave up the tree and can knock out dead branches or tops, endangering the sawyer. Sawyers should look up for falling material after each blow to the wedge.

Figure 3–21—A rifled singletaper

wedge is designed to

provide

lift during

tree felling.

It can be stacked with

additional rifled single-taper

wedges.

Double-taper wedges (figure 3-22) are designed to reduce bind. They taper equally on both sides from the centerline, forcing the wood to move equally in both directions. They perform best when used in bucking to prevent the kerf from closing, which would cause the guide bar to bind.

Figure 3–22—Double-taper

wedges are designed to

reduce bind.

Fuel and Oil Containers—Use Forest Service-approved containers to transport fuel and oil. All lids shall be fully sealed prior to transport.

- Even empty containers are dangerous.

- If a container is missing a lid or showing signs of a

defect such as cracks, take it out of service immediately.

- All employees who handle, transport, or use flammable

or combustible liquids shall receive hazard communication

standards training and be familiar with material

safety data sheets.

- Passengers shall not ride in the enclosed cargo portion

of a vehicle hauling flammable or combustible liquids.

If it is absolutely necessary to carry flammable or

combustible liquids with a passenger vehicle, a minimum

amount of such cargo shall be secured in a rack

on the roof.

- Never transport fuel in the same cargo area with oxidizers,

acids, or radio equipment.

- Flammable or combustible liquids shall be carried in Forest Service-approved containers. Such containers shall be clearly labeled to identify the contents.

Containers shall never be filled more than 90 percent with fuel. Fuel vapors need room to expand. A chain saw should be fueled only after the saw has cooled completely.

Fueling a Chain Saw—

- Allow the saw to cool for at least 5 minutes before

refueling.

- Fill the saw on bare ground or other noncombustible

surface.

- Immediately clean up spilled fuel.

- Refuel outdoors and at least 20 feet from any open

flame or other sources of ignition.

- Do not start the saw closer than 10 feet from the fueling area.

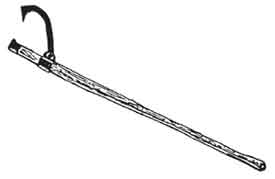

Peaveys and Cant Hooks—The blacksmith Joseph Peavey invented the peavey (figure 3-23a).

Figure 3-23a—Peaveys are used in the woods to pry logs.

Both the peavey and the cant hook (figure 3-23b) use a curved metal hook on the end of a straight handle to roll or skid logs. A peavey has a sharp pointed spike at the lower end, while a cant hook has a tow or lip. Most peaveys and cant hooks come with a duckbill hook that is a good all-around style. Peaveys and cant hooks come with hickory handles that are from 2 to 5½ feet long.

Figure 3–23b—The cant hook has a tow or lip at the lower end

instead of a pointed spike like the peavey.

Peaveys are used almost exclusively in the woods. Peaveys are handy for prying logs up onto blocks to keep the saw from pinching while bucking. The cant hook is used primarily to roll logs.

- Keep the handle free of splinters, splits, and cracks.

- Keep the point sharp.

- Keep your body balanced when pushing or pulling

the pole.

- Grip the handle firmly. Do not overstress it.

- Carry the peavey with the point forward, grasping it

just behind the point of attachment of the hook. Secure

the hook to the shaft to prevent it from swinging free.

- Place a guard on the point when the tool is not in use.