| Background

Firefighters now have a way to remotely activate pumps to charge sprinkler

systems for structure protection. Historically, when a wildfire threatens

structures, firefighting crews would prepare the structures with pumps

and sprinkler systems. Once the threat was imminent, firefighters—at

great risk—rushed to the structures to start the pumps often with

ember showers raining down upon them.

The San Dimas Technology and

Development Center (SDTDC) has developed the technology to remotely activate

a pump for structure protection, avoiding this risk to firefighters. This

system would work well to protect improvements in remote wilderness areas.

The

Pump and Engine

SDTDC purchased a BB-4 pump because of its capability to adapt to a remote

electronic starting system (figure 1). The pump produces up to 425 psi

(or 110 gallons per minute), which is more than enough to operate long

hose lays with significant elevation changes. The BB-4 pump end is a horizontal

4-stage centrifugal pump. An opposed twin cylinder, 18 horsepower, Briggs

and Stratton engine with electric and recoil starting systems powers the

BB-4. The complete pump system weighs 143 pounds and uses approximately

1.8 gallons of fuel per hour during pumping operations. When the remote

start system is not connected, the BB-4 can be used for conventional operations.

|

| Figure

1—BB-4 pump. |

The

Ground Receiver and Handheld Transmitter

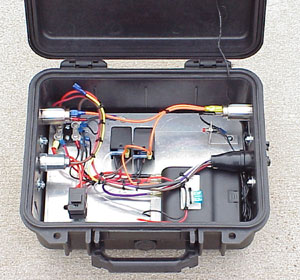

The electronic ground receiver system (figure 2) is housed in a plastic

case. It is a commercial automotive remote starting system. Cables connect

the ground receiver to the electronic starter on the BB-4. The handheld

transmitter (figure 3) is compliant with Federal Communication Commission

regulations regarding communication interference. It is a low power FM

device similar to those used in automotive keyless entry and antitheft

systems. The display on the handheld transmitter was intended to indicate

when a car is running, but it can serve to indicate that the pump is running.

All electronic components are commercially available automotive-grade

hardware.

|

| Figure

2—Electronic ground receiver system. |

|

| Figure

3—Handheld transmiter. |

The

Battery Pack

The battery pack (figure 4) is a 12-volt, power booster capable of providing

400 amp-hours. The stock alligator clips were removed and replaced with

a commercial disconnect plug. This facilitates connection while making

it impossible to cross polarity and damage the electronics or starter.

A 12-volt car battery could be used if caution were taken to ensure proper

polarity before connecting.

|

| Figure

4 —Battery pack |

The

Lights

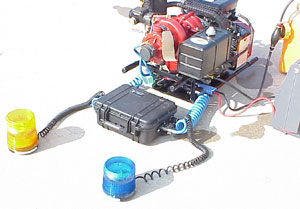

Once the pump develops pressure, lights (figure 5) flash to indicate that

the pump is operating. SDTDC is currently testing several lighting systems

and colors to determine which types of lights and colors are better seen

through smoke. The Center is also investigating strobe light technology

to improve pump visibility. Figure 6 shows the pump, as it would look

during normal operating conditions.

|

| Figure

5—Lights flash to indicate pump is operating. |

|

| Figure

6—The pump during normal operating conditions. |

The Test

On March 14, 2001 the remote pump system was tested at SDTDC using a helicopter

from the Angeles National Forest (figure 7). Following a detailed test

plan, the pump was tested at the maximum test height of 2,000 ft. The

test plan called for three successful pump starts at this altitude. The

pump was successfully started at each attempt. It was a critical part

of the test to see how the remote handheld transmitter worked among the

electronic systems of a firefighting helicopter. No interference with

the helicopter electronic systems, including the air to ground radio systems,

were identified. The technician in the helicopter keyed the remote handheld

transmitter from inside the ship and did not have to lean out or position

himself in any special way to activate the pump below. It is also important

to note that the remote pump can be activated from a ground position as

long as the line of sight is clear of obstacles.

|

| Figure

7—Testing remote pump system from a helicopter. |

Field

Evalutation

Field evaluation is a critical step of the testing process. The pump and a structure protection kit will be

located at SDTDC. Our goal for the next fire season is to test the pump during wildland fire conditions where

structures are threatened.

Information

All of the hardware to build this remote starting pump is commercially

available. Contact the SDTDC fire program leader at 909-599-1267 x234

for specifications, cost, plans, diagrams, or other information.

|