Spark Arrester Brochure

Spark Arrester

All internal combustion engines emit potentially dangerous sparks under normal operating conditions. These sparks, or carbon particles are formed as a product of combustion in the engine cylinder head and are constantly expelled through the exhaust system during engine operation. Spark temperatures range up to 3,000 F. Dry grasses will ignite at about 400 F., making off highway vehicles a potential fire hazard! Add oxygen and a combustible material to hot exhausted sparks and the stage is set for a fire. This is why State (PRC 4442) and Federal law (CFR 261.52(j) require that off highway vehicles must have a Forest Service approved spark arrester, properly installed and maintained.

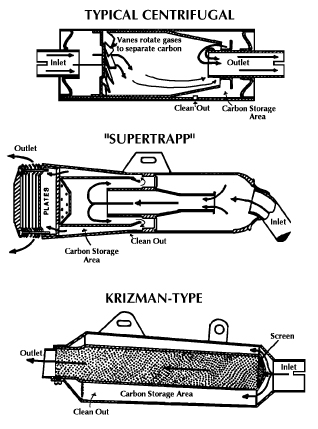

A spark arrester acts like an air filter, removing all solid particles from the exhaust stream. There are basically 3 types of spark arresters in use on today’s OHVs. These are the centrifugal, “Supertrapp” and “Krizman”type.

All federal and state approved spark arresters have been rigidly tested, qualified and rated by the Forest Service Equipment Development Center, and any spark arresters installed on off highway vehicle equipment must meet their requirements.

Maintenance instructions included with the spark arrester should be followed closely. All spark arresters require regular servicing, preferably as part of the routine maintenance of the equipment.

If the arrester is allowed to become too full of carbon particles, the unit will become ineffective; increasing the chance of your being liable for negligence should a fire occur. Inspect the arrester frequently, checking the body for holes, rust, corrosion or other damage, making sure the internal components are not burned out or damaged. Remember, it is your responsibility to equip your vehicle with an approved spark arrester and see that it is properly maintained! All arrester parts must be unmodified to be legal.

INSIDE SPARK ARRESTERS

Issued: 7/10

Alerts & Warnings

- NEW! Office & Visitor Center Updates - Need Info or Passes?

- UPDATED Closure: Small Section of the Forest Still Closed due to Bobcat Fire

- Fire Danger Increases to ‘MODERATE’ at the Angeles National Forest

- Advisory: Hiking at High Elevations

- Driving to the Forest?

- Forest Service Road Closures

- Closure: West Fork Road to recreationists on weekdays thru Dec. 1, 2024

- Closure: San Gabriel Reservoir Area thru June 30, 2024

- Planning to Camp? (Stay Limits/Dispersed Camping Restrictions) til Dec. 15, 2024